As the use of lithium iron phosphate (LFP) batteries in forklifts continues to grow, it is crucial to prioritize safety when charging these high-energy storage devices. Proper charging procedures and equipment are essential to prevent potential hazards and ensure the longevity of your battery investment.

Choosing the Right LFP Battery

When selecting LFP batteries for your forklift fleet, it is crucial to opt for products from reputable manufacturers that have undergone rigorous international safety certifications. These certifications, such as UL, CE, and UN38.3, ensure that the batteries meet stringent safety standards and are less prone to thermal runaway or other hazardous failures.

- 48V 304AH LiFePO4 lithium battery for KOMATSU Forklift FB20-12 Type

- Product on sale48V 404Ah LiFePO4 lithium battery for LIUGONG forkliftOriginal price was: $5,399.00.$5,318.00Current price is: $5,318.00.

- Product on sale48V 606Ah LiFePO4 lithium battery for HELI forkliftOriginal price was: $7,999.00.$7,978.00Current price is: $7,978.00.

- Product on sale

80V 404Ah LiFePO4 lithium battery for HELI K2 3.5T forkliftOriginal price was: $8,399.00.$8,310.00Current price is: $8,310.00.

80V 404Ah LiFePO4 lithium battery for HELI K2 3.5T forkliftOriginal price was: $8,399.00.$8,310.00Current price is: $8,310.00. - Product on sale

48V 404Ah LiFePO4 lithium battery for LIUGONG 2.5TforkliftOriginal price was: $5,399.00.$5,318.00Current price is: $5,318.00.

48V 404Ah LiFePO4 lithium battery for LIUGONG 2.5TforkliftOriginal price was: $5,399.00.$5,318.00Current price is: $5,318.00. - Product on sale

80V 544Ah LiFePO4 lithium battery for TOYOTA forkliftOriginal price was: $11,199.00.$11,190.00Current price is: $11,190.00.

80V 544Ah LiFePO4 lithium battery for TOYOTA forkliftOriginal price was: $11,199.00.$11,190.00Current price is: $11,190.00. - Product on sale

48V 272Ah LiFePO4 lithium battery for LIUGONG forkliftOriginal price was: $3,599.00.$3,581.00Current price is: $3,581.00.

48V 272Ah LiFePO4 lithium battery for LIUGONG forkliftOriginal price was: $3,599.00.$3,581.00Current price is: $3,581.00. - Product on sale

24V 202Ah LiFePO4 lithium battery for LINDE T20 forkliftOriginal price was: $1,399.00.$1,329.00Current price is: $1,329.00.

24V 202Ah LiFePO4 lithium battery for LINDE T20 forkliftOriginal price was: $1,399.00.$1,329.00Current price is: $1,329.00. - Product on sale

48V 544Ah LiFePO4 lithium battery for HELI CPD20-F1 forkliftOriginal price was: $7,199.00.$7,162.00Current price is: $7,162.00.

48V 544Ah LiFePO4 lithium battery for HELI CPD20-F1 forkliftOriginal price was: $7,199.00.$7,162.00Current price is: $7,162.00.

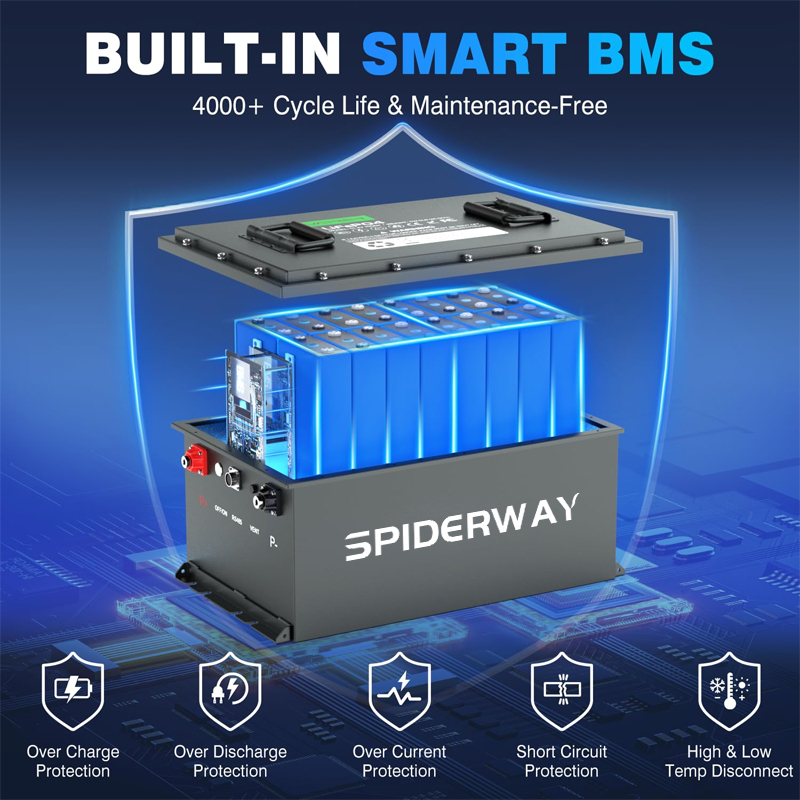

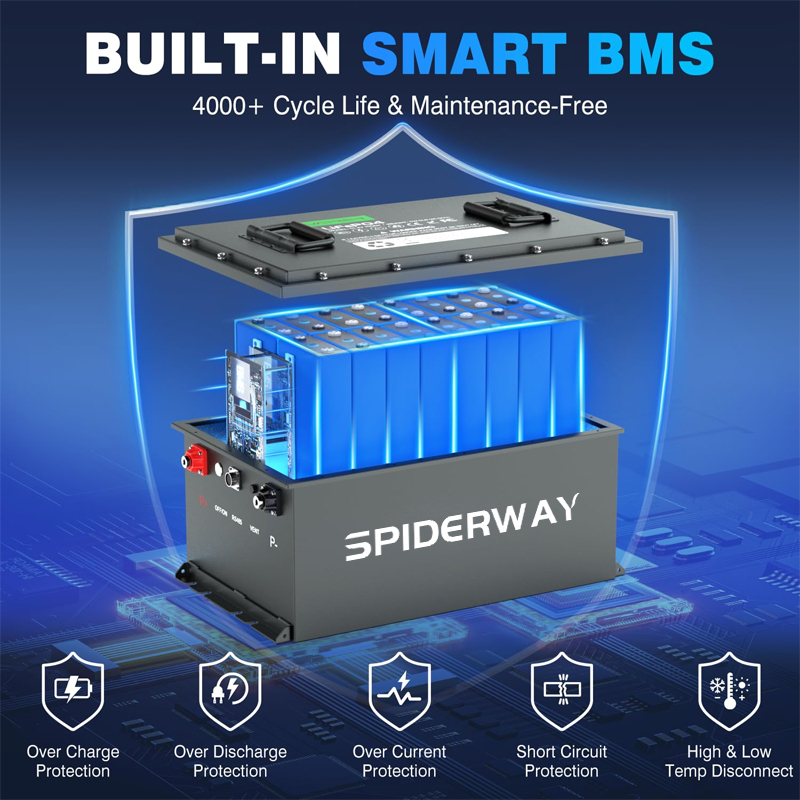

Importance of Battery Management System (BMS)

A reliable Battery Management System (BMS) is a critical component for safe and efficient LFP battery operation. The BMS monitors individual cell voltages, temperatures, and overall battery health, ensuring that the battery is charged and discharged within safe limits. It also provides cell balancing to maintain equal charge levels across all cells, preventing premature wear and tear.

When selecting a BMS, look for one that is specifically designed for LFP batteries and has been tested and validated by the battery manufacturer. Compatibility between the battery and BMS is essential for optimal performance and safety.

Choosing the Right Charger

Selecting a charger that is compatible with your LFP battery and BMS is crucial for safe and efficient charging. Chargers designed for LFP batteries typically have a constant current-constant voltage (CC-CV) charging profile, which ensures that the battery is charged at a safe rate and to the appropriate voltage level.

When choosing a charger, consider the following factors:

- Compatibility with your LFP battery voltage and capacity

- Presence of safety features such as overcharge, overcurrent, and overheat protection

- Ability to communicate with the BMS for optimal charging control

- Efficiency and power factor to minimize energy losses and costs

- Product on sale

FlexChar 36V 25A 900W Industrial Battery Charger For Golf Cart/Electric Forklift/Electric VehicleOriginal price was: $350.00.$339.00Current price is: $339.00.

FlexChar 36V 25A 900W Industrial Battery Charger For Golf Cart/Electric Forklift/Electric VehicleOriginal price was: $350.00.$339.00Current price is: $339.00. - Product on sale

FlexChar 24V 18A 420W Industrial Battery Charger For Golf Cart/Electric Forklift/Electric VehicleOriginal price was: $300.00.$289.00Current price is: $289.00.

FlexChar 24V 18A 420W Industrial Battery Charger For Golf Cart/Electric Forklift/Electric VehicleOriginal price was: $300.00.$289.00Current price is: $289.00. - Product on sale

29.4V 6A XilLin Electric Pallet Truck Lithium battery ChargerOriginal price was: $199.00.$100.00Current price is: $100.00.

29.4V 6A XilLin Electric Pallet Truck Lithium battery ChargerOriginal price was: $199.00.$100.00Current price is: $100.00. - Product on sale

48V 6A XilLin Electric Pallet Truck Lithium battery ChargerOriginal price was: $199.00.$100.00Current price is: $100.00.

48V 6A XilLin Electric Pallet Truck Lithium battery ChargerOriginal price was: $199.00.$100.00Current price is: $100.00. - Product on sale

24V 5A EP Electric Pallet Truck Lithium Battery ChargerOriginal price was: $120.00.$100.00Current price is: $100.00.

24V 5A EP Electric Pallet Truck Lithium Battery ChargerOriginal price was: $120.00.$100.00Current price is: $100.00. - Product on sale

80V 200A Three Phase Lithium Battery Charger For ForkliftOriginal price was: $1,850.00.$1,710.00Current price is: $1,710.00.

80V 200A Three Phase Lithium Battery Charger For ForkliftOriginal price was: $1,850.00.$1,710.00Current price is: $1,710.00. - Product on sale

80V 100A LiFePO4 Forklift Battery Charger Set for ToyotaOriginal price was: $1,160.00.$1,040.00Current price is: $1,040.00.

80V 100A LiFePO4 Forklift Battery Charger Set for ToyotaOriginal price was: $1,160.00.$1,040.00Current price is: $1,040.00. - Product on sale

480V (320-530V) LiFePO4 Battery Charger Set for ForkliftOriginal price was: $1,845.00.$1,750.00Current price is: $1,750.00.

480V (320-530V) LiFePO4 Battery Charger Set for ForkliftOriginal price was: $1,845.00.$1,750.00Current price is: $1,750.00. - Product on sale

48V 100A-220V Forklift Batteries Chargers For Hyundai 15BROriginal price was: $1,250.00.$1,160.00Current price is: $1,160.00.

48V 100A-220V Forklift Batteries Chargers For Hyundai 15BROriginal price was: $1,250.00.$1,160.00Current price is: $1,160.00.

SPIDERWAY: Your Safe Choice for LFP Battery Solutions

SPIDERWAY, a leading manufacturer of LFP batteries and charging solutions, offers a comprehensive range of products designed with safety and performance in mind. Their LFP batteries are manufactured using high-quality materials and undergo rigorous testing to ensure compliance with international safety standards.

SPIDERWAY‘s BMS and charger solutions are specifically designed to work seamlessly with their LFP batteries, providing an integrated and safe charging system. Their chargers feature advanced safety protections and are optimized for efficient and fast charging, minimizing downtime and maximizing productivity.

By choosing SPIDERWAY for your forklift LFP battery and charging needs, you can be confident that you are investing in a safe and reliable solution that will provide years of trouble-free operation. Contact SPIDERWAY today to learn more about their LFP battery and charging solutions for forklifts.