Lithium Ion Battery in Electric Vehicles

In recent years, lithium-ion batteries have become a fundamental component in the electrification of industrial vehicles, such as forklifts, ground support equipment (GSE), and aerial work platforms. The transition from traditional lead-acid batteries to lithium-ion variants has significantly impacted the industrial sector due to their superior performance, sustainability, and cost-effectiveness. This article will delve into the various types of lithium-ion batteries used in industrial vehicles, their application scenarios, current adoption rates, and future trends.

Types of Lithium-Ion Batteries in Industrial Vehicles

There are several types of lithium-ion batteries used in industrial vehicles, each with unique characteristics tailored to specific applications:

- Lithium Iron Phosphate (LiFePO4) Batteries:

- Known for their high safety standards, long cycle life, and thermal stability, LiFePO4 batteries are widely adopted in industrial vehicles such as forklifts and GSE. Their ability to withstand high temperatures and rigorous working environments makes them a reliable choice for heavy-duty industrial tasks.

- Nickel Manganese Cobalt (NMC) Batteries:

- Offering a balance between energy density and cost, NMC batteries are commonly used in both electric cars and industrial applications. Their higher energy density compared to LiFePO4 makes them suitable for industrial vehicles that require more power for extended operations.

- Lithium Nickel Cobalt Aluminum Oxide (NCA) Batteries:

- These batteries offer very high energy densities and are often utilized in electric cars but can be found in high-end industrial applications as well. However, their cost and reduced thermal stability compared to LiFePO4 and NMC limit their broader industrial use.

Application Scenarios of Lithium-Ion Batteries in Industrial Vehicles

Lithium-ion batteries are utilized across various types of industrial vehicles, including:

- Forklifts: Lithium-ion batteries enable fast charging, longer operational hours, and lower maintenance compared to lead-acid alternatives.

- Ground Support Equipment (GSE): Used in airports, lithium-ion-powered GSE helps reduce carbon emissions while ensuring efficient, round-the-clock operations.

- Aerial Work Platforms: These batteries power equipment used in construction and maintenance at heights, offering reliable energy output in various working conditions.

Adoption Rates of Lithium-Ion Batteries in Industrial Vehicles

The adoption of lithium-ion batteries in the industrial vehicle sector is accelerating. According to a 2022 market report by Allied Market Research, the global lithium-ion battery market for industrial vehicles was valued at $4.3 billion and is expected to grow at a compound annual growth rate (CAGR) of 9.8% between 2022 and 2030. A significant portion of this growth is driven by the increasing demand for forklifts and other material handling equipment in warehouses, logistics, and manufacturing.

| Year | Global Market Value (Billion USD) | Growth Rate (CAGR) |

|---|---|---|

| 2022 | 4.3 | 9.8% |

| 2025 | 5.6 | 10.1% |

| 2030 | 9.8 | 11.2% |

Data Source: Allied Market Research (2022)

Future Trends and Forecast

The industrial vehicle lithium-ion battery market is set to experience continued growth as technological advancements improve energy density, reduce costs, and make batteries more accessible to small and medium-sized enterprises. Several key trends are expected to shape the future of this market:

- Increased Adoption of Electric Forklifts:

- As regulatory pressure to reduce emissions increases, more companies will switch from diesel or LPG-powered forklifts to electric models using lithium-ion batteries.

- Development of Smart Battery Management Systems (BMS):

- Future lithium-ion batteries for industrial vehicles will likely include advanced BMS, optimizing charging cycles, extending battery life, and providing real-time diagnostics to reduce downtime.

- Advancements in Fast Charging Technologies:

- The ability to charge lithium-ion batteries quickly, without significantly impacting cycle life, will make electric industrial vehicles more competitive against their internal combustion engine counterparts.

- Rise in Modular Battery Systems:

- Modular battery solutions will allow companies to swap battery packs quickly, minimizing downtime and improving fleet efficiency in logistics and manufacturing.

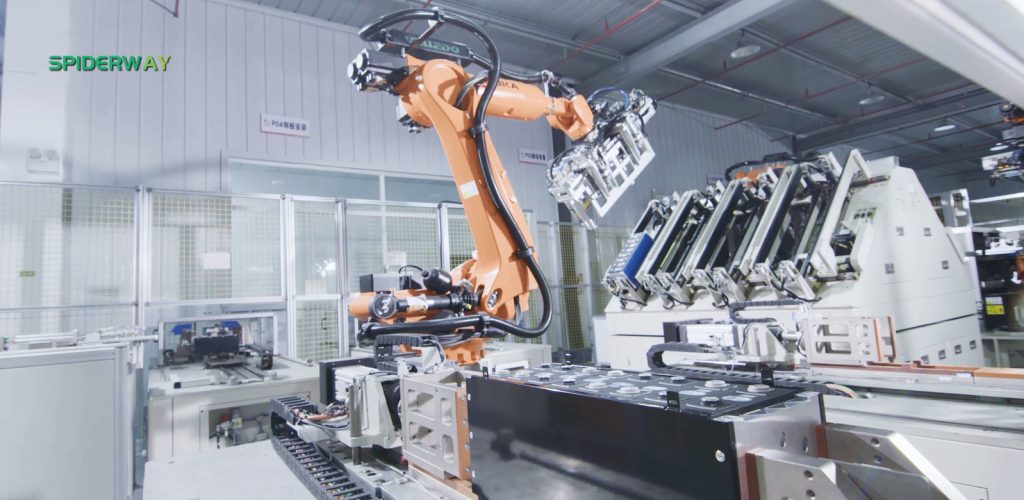

SPIDERWAY: Leading the Way in Industrial Vehicle Lithium-Ion Batteries

As the market for lithium-ion batteries in industrial vehicles grows, SPIDERWAY stands at the forefront as a leading manufacturer specializing in LFP (Lithium Iron Phosphate) power solutions for industrial vehicles. With a focus on safety, efficiency, and innovation, SPIDERWAY offers high-performance batteries for forklifts, GSE, and other industrial applications.

Why Choose SPIDERWAY?

- Superior Safety and Reliability: SPIDERWAY’s LFP batteries are known for their exceptional safety standards, making them ideal for heavy-duty industrial use.

- Long Cycle Life: With thousands of charging cycles, SPIDERWAY batteries reduce the total cost of ownership and downtime.

- Environmental Sustainability: LFP batteries are free of toxic metals like cobalt and nickel, contributing to a greener and cleaner industrial environment.

- Global Warehousing and Fast Delivery: SPIDERWAY has an extensive global warehousing network, ensuring fast and efficient delivery to customers worldwide.

As a professional manufacturer of industrial vehicle lithium-ion batteries, SPIDERWAY is committed to continuous innovation, providing cutting-edge solutions for industrial applications worldwide.

For more details on SPIDERWAY’s product offerings, visit our website or contact our team for tailored battery solutions that meet your operational needs.

Content Summary:

This article provided a comprehensive overview of lithium-ion battery types, applications, and adoption trends in industrial vehicles. It also highlighted the advantages of choosing SPIDERWAY’s LFP power solutions for forklifts and other industrial vehicles.

Author Profile

- https://tawk.to/chat/6228c78d1ffac05b1d7dc569/1ftnkn0nk

- SpiderWay LiFePO4 battery sales engineer with ten years of experience in industrial vehicle batteries, ready to answer any questions you may have about industrial LiFePO4 battery products.

Latest entries

Battery Charger KnowledgeNovember 15, 2024LFP (LiFePO4) Battery Charger Supplier from China: The Ultimate Solution for EV and Renewable Energy Applications

Industry NewsNovember 15, 2024China ESS Energy Storage Battery Manufacturers: Industry Development Data and Future Market Trends

Cleaning MachinesNovember 15, 2024Global Leading Cleaning Machines Brands & LFP Lithium Battery Solutions: Powering the Future of Cleaning Technology

Industry NewsNovember 15, 2024Embracing the Energy Transition for a Sustainable Future