리튬 이온(리튬 이온) 배터리 are integral to various industries due to their energy density, long lifespan, and rechargeable nature. However, as their use becomes more widespread, particularly in high-demand environments like warehouses, factories, and airports, ensuring the fire safety of lithium-ion 배터리 is crucial. In this article, we will explore the safety risks associated with lithium-ion batteries, particularly in industrial vehicle applications, and highlight the benefits of LiFePO4 (인산철 리튬) 배터리 as a safer alternative. We will also delve into the different safety levels of various lithium batteries, with a focus on fire prevention and thermal management.

The Risk of Fire in Lithium-Ion Batteries

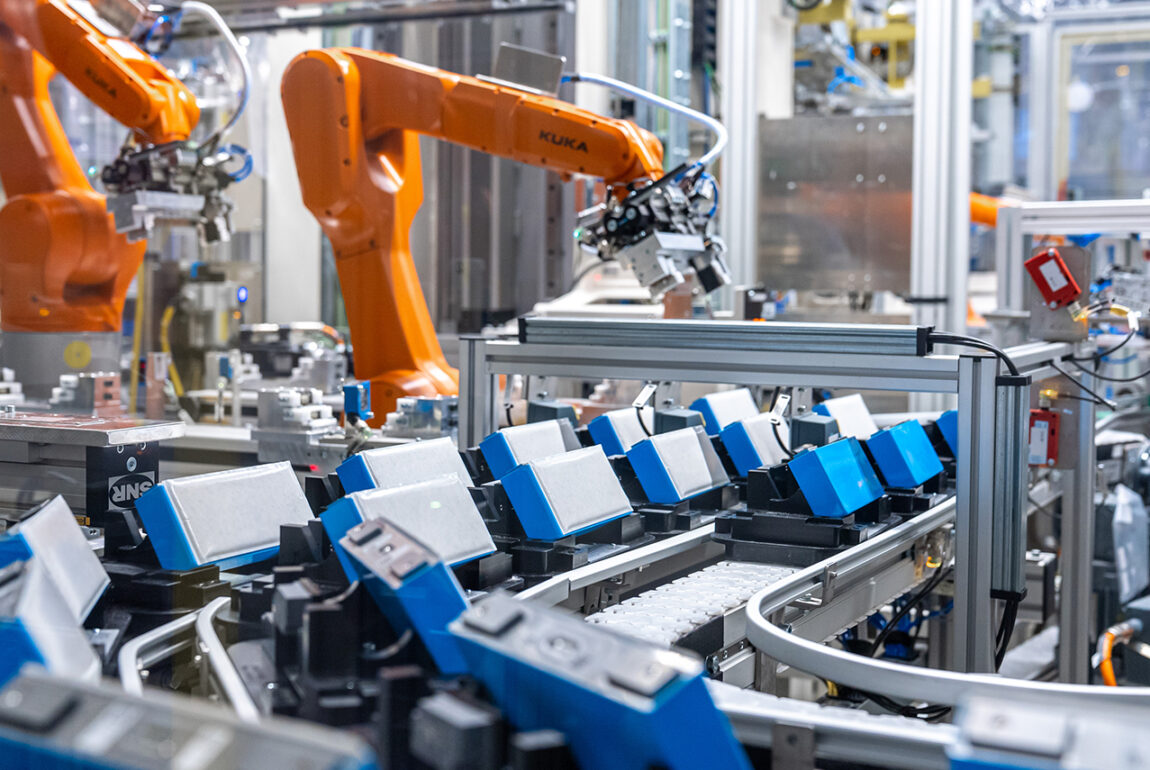

Lithium-ion batteries, like those used in electric forklifts, automated guided vehicles (AGVs), and other industrial equipment, have revolutionized industries by offering efficient power solutions. However, a primary concern with these batteries is the risk of thermal runaway and the potential for battery fires. Thermal runaway occurs when a battery’s internal temperature increases uncontrollably, leading to the release of flammable gases and, in severe cases, fires or explosions.

In industrial environments, where equipment is used heavily and often under high stress, the risks associated with lithium-ion battery fires can be significantly magnified. Understanding these risks and taking the proper precautions to mitigate them is essential for workplace safety and operational continuity.

Types of Lithium-Ion Batteries and Their Safety Levels

Lithium-ion batteries come in several types, including Lithium Cobalt Oxide (LiCoO2), Lithium Manganese Oxide (LiMn2O4), Nickel Cobalt Aluminum (NCA)및 인산철 리튬 (LiFePO4). While all these batteries have their uses, their safety features can vary significantly.

- Lithium Cobalt Oxide (LiCoO2): These batteries are commonly used in consumer electronics like smartphones and laptops. While they have high energy density, they are also the most prone to overheating and thermal runaway, making them less ideal for industrial applications.

- Nickel Cobalt Aluminum (NCA): NCA batteries are used in electric vehicles and some high-performance applications. While they have a relatively higher energy density, their fire safety can be a concern in extreme conditions, requiring sophisticated thermal management systems.

- 리튬 인산철(LiFePO4): Among the various types, LiFePO4 batteries are known for their superior safety 및 thermal stability. They are less likely to experience thermal runaway compared to other lithium-ion chemistries, which makes them an ideal choice for industrial applications where safety is a top priority.

Fire Safety in Forklift and Industrial Vehicle Batteries

One of the most critical areas for lithium-ion battery safety is in 지게차 배터리. Forklifts and other industrial vehicles operate in demanding environments, often exposed to extreme temperatures, rough handling, and charging cycles. Given these conditions, ensuring that forklift batteries are fire-safe is paramount.

Here are key safety practices to reduce fire risks in forklift and industrial vehicle batteries:

- Battery Charging and Maintenance: Always use chargers that are compatible with the battery type and ensure that batteries are maintained according to the manufacturer’s specifications. Overcharging or undercharging can lead to dangerous conditions, including thermal runaway.

- Temperature Management: Ensure that batteries are stored and operated in temperature-controlled environments. Excessive heat can lead to battery failure or fire. Lithium-ion batteries equipped with Battery Management Systems (BMS) can help monitor and regulate temperature, reducing the risk of overheating.

- 환기: Ensure proper ventilation in areas where lithium-ion batteries are charged and stored. Batteries that are in thermal runaway can release toxic gases that require adequate ventilation for safe dissipation.

- Fire Safety Equipment: Equip workplaces with fire safety systems that are specifically designed for lithium-ion battery fires, such as automatic fire suppression systems, fire-resistant storage cabinets, and fire extinguishers rated for electrical fires.

Why LiFePO4 Batteries Are the Safest Choice for High-Risk Environments

When it comes to fire safety, LiFePO4 batteries stand out due to their inherent chemical stability and lower risk of thermal runaway. In comparison to other lithium chemistries, LiFePO4 offers superior heat tolerance, even under harsh conditions. In addition to being safer, LiFePO4 batteries have a longer cycle life and are less prone to degradation, making them a cost-effective option for industrial use.

In high-risk applications such as 창고, 공장및 공항, where equipment safety is crucial, LiFePO4 batteries offer several advantages:

- 향상된 열 안정성: LiFePO4 batteries are much less likely to overheat or catch fire due to their superior thermal management properties.

- Non-Explosive: Unlike other lithium-ion chemistries, LiFePO4 배터리 are chemically stable and do not explode under extreme conditions, such as being pierced or subjected to high heat.

- Fire-Resistant: These batteries are designed to be fire-resistant, making them an ideal solution for environments where fire safety is a top concern.

- 더 길어진 수명: With a longer cycle life compared to other battery types, LiFePO4 배터리 offer a reliable, safe, and sustainable power source for industrial equipment.

SPIDERWAY LiFePO4 Batteries: A Superior Choice for Fire Safety

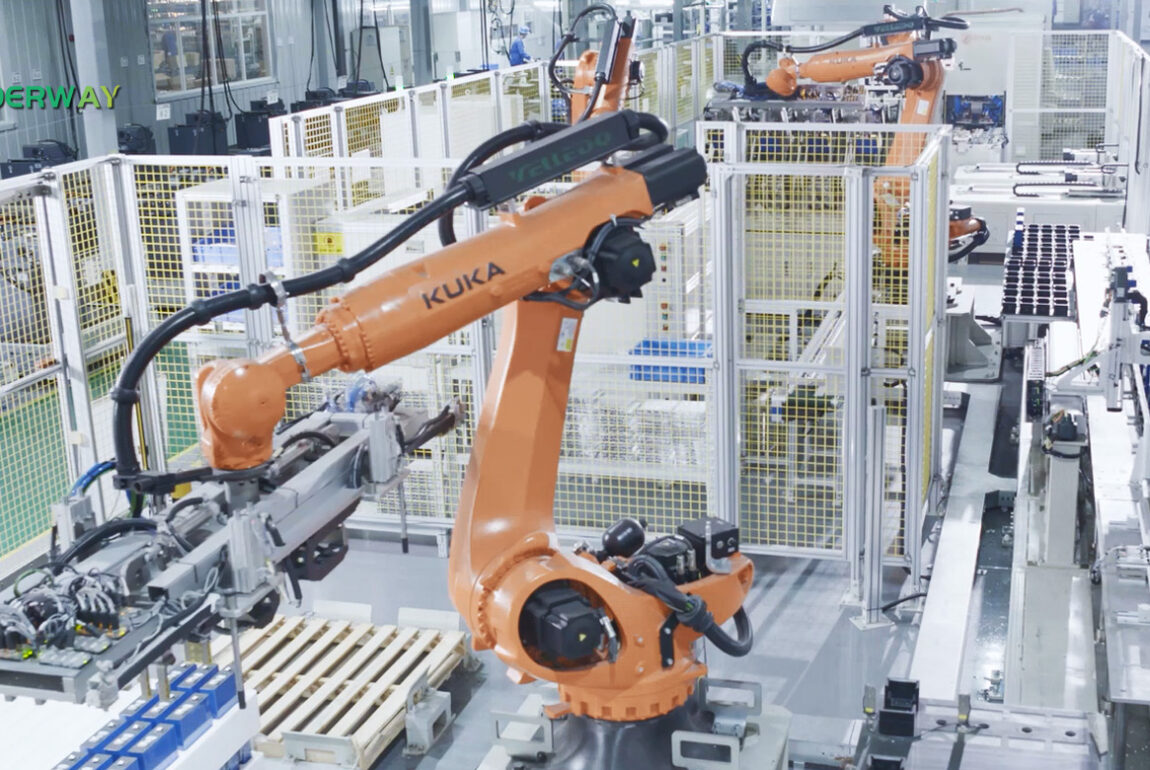

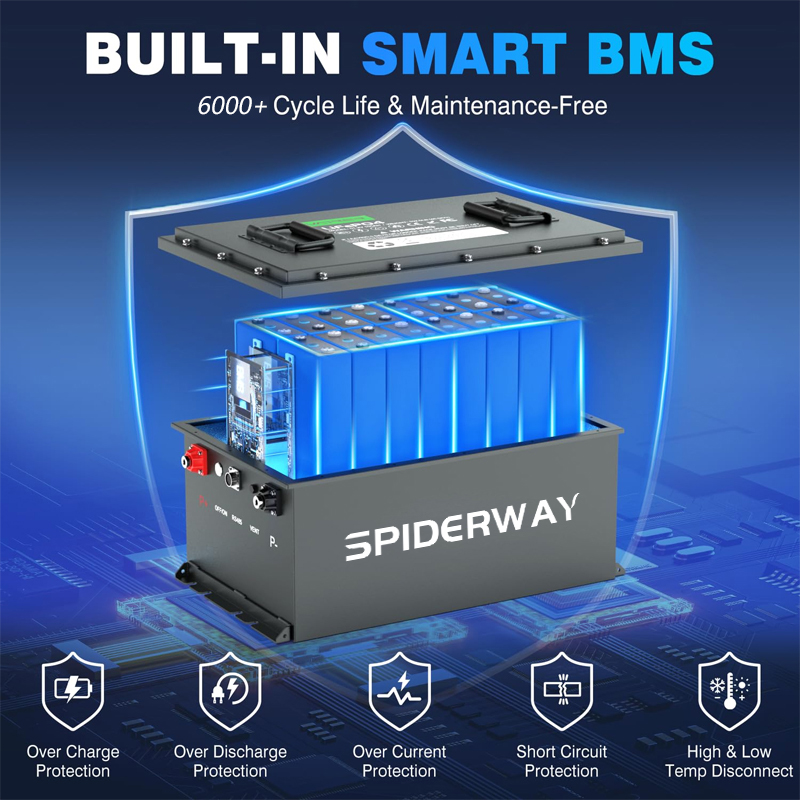

스파이더웨이 LiFePO4 배터리 combine all the safety benefits of lithium iron phosphate technology with advanced features designed to enhance battery performance and safety in demanding industrial environments. These batteries are equipped with a 배터리 관리 시스템(BMS), which provides real-time monitoring of battery parameters such as temperature, voltage, and current, ensuring safe operation under all conditions.

Additionally, 스파이더웨이 LiFePO4 배터리 are internationally certified with UL, CE, and RoHS certifications, ensuring that they meet global safety and quality standards. This makes them a perfect choice for industries where safety compliance is critical.

As the use of lithium-ion batteries continues to expand, understanding their safety risks and choosing the right battery chemistry for your application is essential. While lithium-ion batteries offer excellent energy density, fire safety concerns remain paramount, especially in high-demand industrial settings. LiFePO4 배터리, with their enhanced thermal stability and fire-resistant properties, provide a safer and more reliable power solution for industrial vehicles like forklifts, AGVs, and more.

For applications requiring the highest level of fire safety and operational reliability, 스파이더웨이 LiFePO4 배터리 provide the perfect balance of performance and safety. With their advanced BMS system, international safety certifications, and proven track record in high-risk environments, SPIDERWAY batteries offer peace of mind and optimal safety for businesses that prioritize both performance and fire prevention.

콘텐츠 키워드: Lithium 배터리 Safety, Lithium 배터리 Fire Prevention, Lithium Ion Thermal Runaway, Safest Lithium 배터리, 지게차 배터리 Fire Safety, LiFePO4 배터리 Safety, 배터리 Management System, SPIDERWAY LiFePO4.

작성자 프로필

- https://tawk.to/chat/6228c78d1ffac05b1d7dc569/1ftnkn0nk

- 산업용 차량 배터리 분야에서 10년의 경력을 쌓은 SpiderWay LiFePO4 배터리 영업 엔지니어가 산업용 LiFePO4 배터리 제품에 대한 모든 질문에 답변해 드립니다.

최신 항목

제품 지식11월 14, 2024Fire Safety in Lithium-Ion Batteries: Understanding Risks and Best Practices for Industrial Use

업계 뉴스11월 14, 2024Vietnam LFP (LiFePO4) Lithium Ion Battery Factory Distribution and Market Demand Analysis

업계 뉴스11월 14, 2024Phân tích phân phối nhà máy pin LFP (LiFePO4) và nhu cầu thị trường tại Việt Nam

업계 뉴스11월 13, 2024브라질 시장에서 중국산 LiFePO4 전력 배터리에 대한 수요 분석