In the modern era of logistics and manufacturing, the demand for efficient and environmentally friendly power sources has never been higher. Industrial vehicle lithium batteries have emerged as a leading solution, providing clean and efficient energy for a variety of material handling equipment such as forklifts, stackers, and tractors. This article delves into the critical performance indicators and data associated with these batteries, highlighting their significance in the industry.

1. Energy Density

Energy density is a measure of the amount of energy stored per unit volume or mass of the battery. For industrial vehicles, a higher energy density is desirable as it allows for longer operation times without the need for frequent recharging. Lithium batteries typically offer energy densities ranging from 100 to 260 watt-hours per kilogram (Wh/kg), which is significantly higher than traditional lead-acid batteries.

2. Power Density

Power density refers to the amount of power that can be delivered per unit mass or volume. Industrial vehicles require high power outputs for tasks such as lifting and moving heavy loads. Lithium batteries can deliver power densities of up to 1000 watts per kilogram (W/kg), ensuring that vehicles have the necessary power for peak performance.

3. Cycle Life

The cycle life of a battery is the number of charge and discharge cycles it can undergo before its capacity falls below a certain threshold, typically 80% of its original capacity. Industrial lithium batteries are designed for longevity, with cycle lives ranging from 1000 to 3000 cycles, depending on the depth of discharge and usage pattern.

4. Charge and Discharge Rates

The rate at which a battery can be charged or discharged is crucial for operational efficiency. Fast charging capabilities reduce downtime, while high discharge rates ensure that vehicles can handle heavy loads without performance degradation. Lithium batteries can support charge rates of up to 1C (full charge in one hour) and discharge rates that can exceed 10C, depending on the battery chemistry and design.

5. Temperature Tolerance

Industrial environments can be harsh, with temperatures varying significantly. Lithium batteries must operate effectively across a wide temperature range, typically from -20°C to 60°C. This ensures that vehicles can function reliably in various climates and conditions.

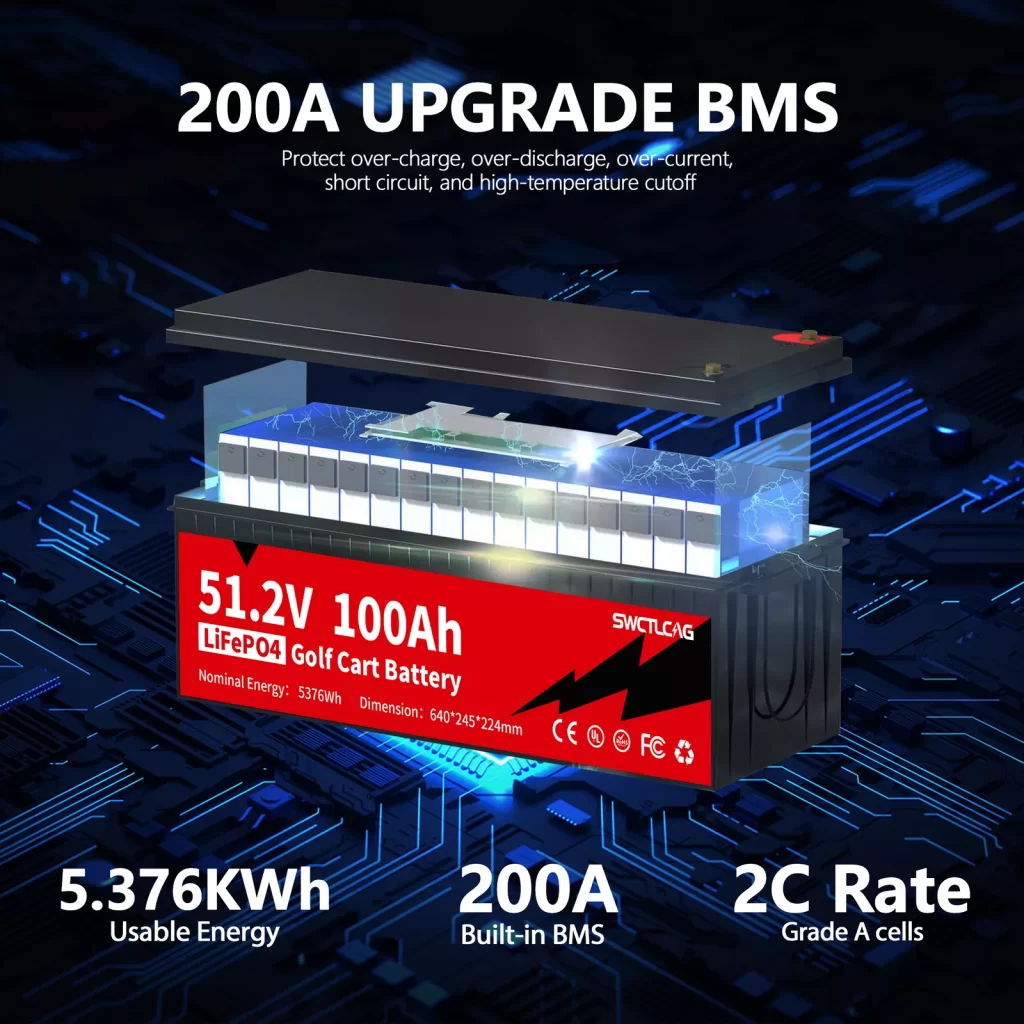

6. Safety Features

Safety is paramount in industrial applications. Lithium batteries incorporate multiple safety features such as overcharge protection, over-discharge protection, short circuit protection, and thermal management systems to prevent incidents like fires or explosions.

7. Environmental Impact

As part of the push towards sustainability, the environmental impact of batteries is a key consideration. Lithium batteries have a lower environmental footprint compared to lead-acid batteries, with a longer lifespan and the potential for recycling and reuse of materials.

8. Cost-Effectiveness

While the initial cost of lithium batteries may be higher than traditional alternatives, their operational efficiency, longevity, and reduced maintenance requirements can lead to significant cost savings over their service life.

- Product on sale

48V 404Ah LiFePO4 lithium battery for LIUGONG forkliftOriginal price was: $5,399.00.$5,318.00Current price is: $5,318.00.

48V 404Ah LiFePO4 lithium battery for LIUGONG forkliftOriginal price was: $5,399.00.$5,318.00Current price is: $5,318.00. - Product on sale

48V 606Ah LiFePO4 lithium battery for HELI forkliftOriginal price was: $7,999.00.$7,978.00Current price is: $7,978.00.

48V 606Ah LiFePO4 lithium battery for HELI forkliftOriginal price was: $7,999.00.$7,978.00Current price is: $7,978.00. - Product on sale

80V 404Ah LiFePO4 lithium battery for HELI K2 3.5T forkliftOriginal price was: $8,399.00.$8,310.00Current price is: $8,310.00.

80V 404Ah LiFePO4 lithium battery for HELI K2 3.5T forkliftOriginal price was: $8,399.00.$8,310.00Current price is: $8,310.00. - Product on sale

48V 404Ah LiFePO4 lithium battery for LIUGONG 2.5TforkliftOriginal price was: $5,399.00.$5,318.00Current price is: $5,318.00.

48V 404Ah LiFePO4 lithium battery for LIUGONG 2.5TforkliftOriginal price was: $5,399.00.$5,318.00Current price is: $5,318.00. - Product on sale

80V 544Ah LiFePO4 lithium battery for TOYOTA forkliftOriginal price was: $11,199.00.$11,190.00Current price is: $11,190.00.

80V 544Ah LiFePO4 lithium battery for TOYOTA forkliftOriginal price was: $11,199.00.$11,190.00Current price is: $11,190.00. - Product on sale

48V 272Ah LiFePO4 lithium battery for LIUGONG forkliftOriginal price was: $3,599.00.$3,581.00Current price is: $3,581.00.

48V 272Ah LiFePO4 lithium battery for LIUGONG forkliftOriginal price was: $3,599.00.$3,581.00Current price is: $3,581.00. - Product on sale

24V 202Ah LiFePO4 lithium battery for LINDE T20 forkliftOriginal price was: $1,399.00.$1,329.00Current price is: $1,329.00.

24V 202Ah LiFePO4 lithium battery for LINDE T20 forkliftOriginal price was: $1,399.00.$1,329.00Current price is: $1,329.00. - Product on sale

48V 544Ah LiFePO4 lithium battery for HELI CPD20-F1 forkliftOriginal price was: $7,199.00.$7,162.00Current price is: $7,162.00.

48V 544Ah LiFePO4 lithium battery for HELI CPD20-F1 forkliftOriginal price was: $7,199.00.$7,162.00Current price is: $7,162.00. - Product on sale

48V 165Ah LiFePO4 lithium battery for AGVOriginal price was: $2,199.00.$2,172.00Current price is: $2,172.00.

48V 165Ah LiFePO4 lithium battery for AGVOriginal price was: $2,199.00.$2,172.00Current price is: $2,172.00.

Author Profile

- https://tawk.to/chat/6228c78d1ffac05b1d7dc569/1ftnkn0nk

- SpiderWay LiFePO4 battery sales engineer with ten years of experience in industrial vehicle batteries, ready to answer any questions you may have about industrial LiFePO4 battery products.

Latest entries

Industry NewsNovember 13, 2024Analysis of the Demand for Chinese LiFePO4 Power Batteries in the Brazilian Market

DOOSANNovember 13, 2024South Korea LiFePO4 Battery Brands and Successful OEM Collaborations with Chinese Manufacturers

Industry NewsNovember 12, 2024Analyzing the Demand for Chinese LiFePO4 Power Batteries in Turkey’s Market

Industry NewsNovember 12, 2024การวิเคราะห์อุตสาหกรรมผลิตและความต้องการตลาดของแบตเตอรี่ลิเทียมไอออน LiFePO (LFP) ในไทย