The global demand for lithium iron phosphate (LiFePO4 or LFP) batteries has been steadily rising, driven by their superior safety, longer cycle life, and cost-effectiveness compared to other lithium-ion battery types. The United States, recognizing the strategic importance of this technology, has been ramping up its efforts to bolster domestic LFP battery manufacturing capacity. This push aligns with the increasing need for sustainable energy solutions, particularly in industrial applications and electric vehicles.

Growing Demand for LFP Batteries in the U.S.

LFP batteries have become the go-to choice for a wide array of industrial applications due to their inherent safety, stability, and ability to operate under extreme conditions. Industries ranging from warehouse operations to construction rely heavily on machinery such as forklifts and ground support equipment (GSE), all of which benefit from LFP battery power systems. In addition, electric vehicles (EVs) and grid energy storage are contributing to the rising demand for high-performance batteries, further driving investment in LFP technology.

U.S. LFP Battery Manufacturing Landscape

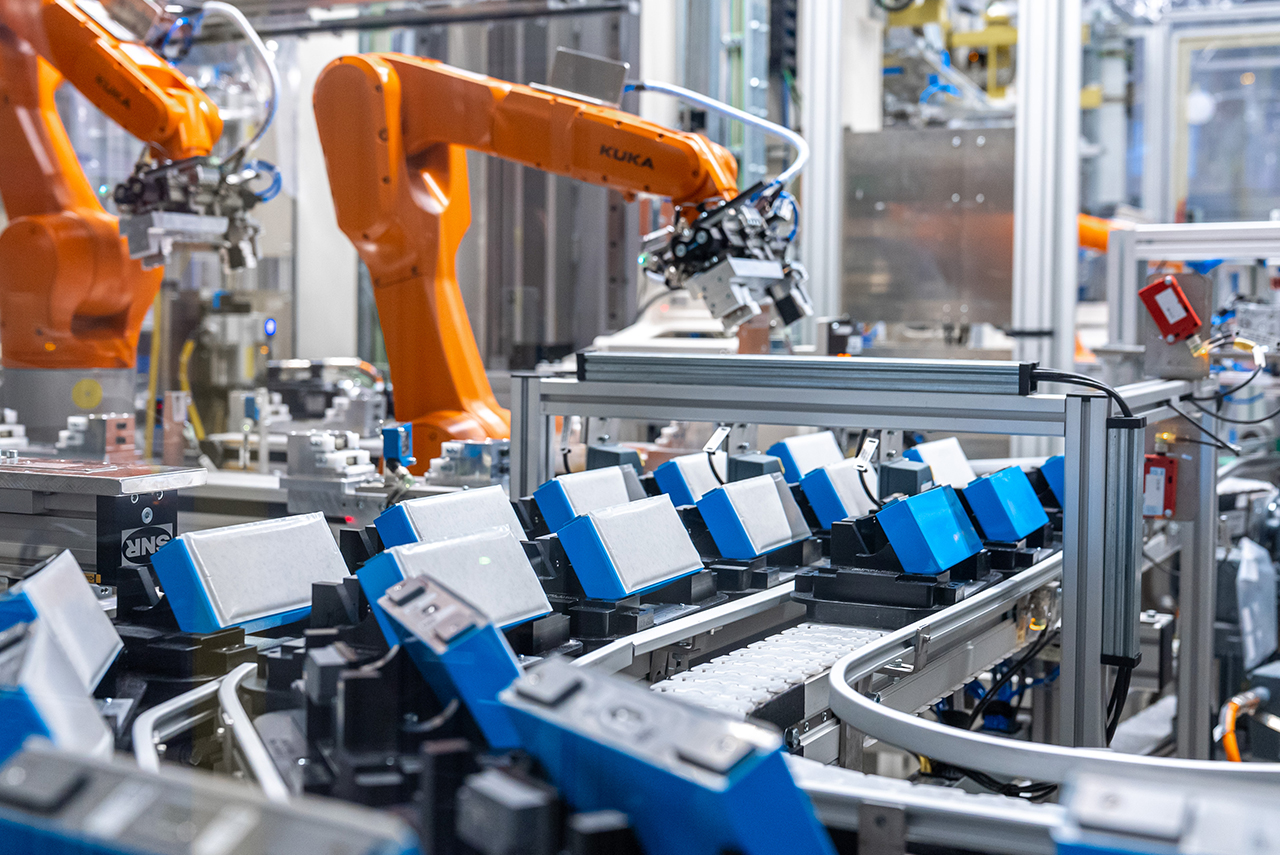

Historically, China has led the global production of LFP batteries. However, with growing concerns over supply chain dependency and national security, the U.S. government and private sector have begun prioritizing local production. Several key developments highlight the rapid expansion of LFP manufacturing capabilities within the United States:

- Government Support: U.S. federal and state governments are offering incentives to build local battery manufacturing plants. These initiatives include grants, tax breaks, and investments into research and development to reduce reliance on foreign suppliers.

- Expansion of Domestic Facilities: U.S.-based companies like QuantumScape and startups such as American Battery Technology Company are investing in large-scale production facilities dedicated to manufacturing LFP batteries. These facilities aim to meet the growing demand for industrial and automotive sectors by supplying high-quality, locally-produced battery cells.

- Collaboration with Global Players: Major battery manufacturers from Asia, such as CATL, have also announced partnerships with U.S. companies to set up local production facilities. This collaboration is vital for bringing expertise, technology, and scalability to American manufacturing.

- Focus on Sustainability: U.S. manufacturers are investing in cleaner, more efficient production methods to meet environmental standards. With increased focus on reducing the carbon footprint of battery production, several factories are adopting renewable energy sources to power their manufacturing processes.

Industrial Vehicle Market: A Critical Use Case for LFP Batteries

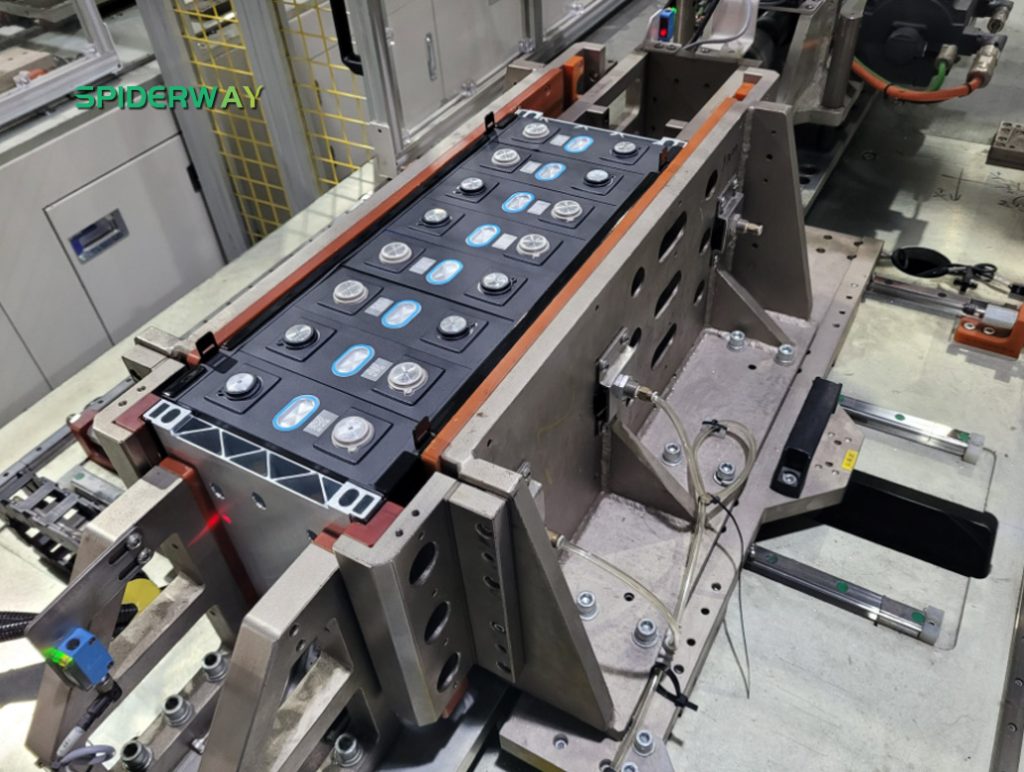

Among the many sectors benefiting from the growth of LFP battery manufacturing in the U.S., industrial vehicles stand out. The heavy reliance on forklifts, aerial work platforms, and GSE across industries like logistics, construction, and airports highlights the importance of high-performance and reliable battery solutions. LFP batteries are becoming a critical component for powering these vehicles due to their durability, safety, and cost-efficiency compared to traditional lead-acid batteries.

Challenges and Future Outlook

While the growth of U.S. LFP battery manufacturing is promising, several challenges remain. Securing a stable supply of raw materials such as lithium and iron phosphate remains a concern, as the U.S. currently imports most of these materials. Additionally, competition with other battery technologies, such as nickel-cobalt-manganese (NCM) batteries, may slow the adoption of LFP in certain high-energy-demand applications.

Nevertheless, with ongoing technological improvements, strong government backing, and increased demand, the U.S. LFP battery manufacturing sector is poised for significant growth. As the global market shifts towards greener energy solutions, the U.S. will play an increasingly critical role in producing and supplying high-quality LFP batteries.

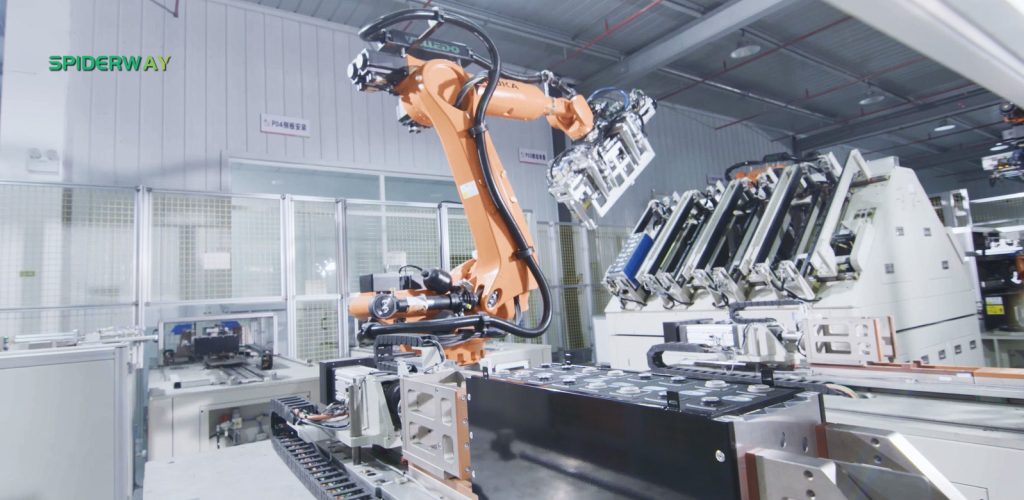

SPIDERWAY’s Contribution to the U.S. Industrial Vehicle Power Battery Market

In this competitive landscape, SPIDERWAY has established itself as a leader in the U.S. industrial vehicle power battery market. Our high-quality LiFePO4 batteries are specifically designed for industrial vehicles such as forklifts, ground support equipment, and aerial work platforms. With a focus on safety, performance, and sustainability, SPIDERWAY’s LFP batteries have earned the trust of customers across the U.S.

Our partnership with leading U.S. companies has enabled us to provide efficient and reliable power solutions for a wide range of industrial applications. SPIDERWAY’s commitment to innovation and excellence has contributed significantly to the growth of LFP battery usage in the U.S., helping industries reduce their environmental impact while improving operational efficiency.

Content Keywords:

- U.S. LFP battery manufacturing

- U.S. LiFePO4 battery production

- Industrial vehicle power batteries

- U.S. LFP battery industry

- SPIDERWAY LiFePO4 batteries

This article’s insights into the U.S. LFP battery manufacturing landscape show that SPIDERWAY is well-positioned to continue making a positive impact on the industrial vehicle market by delivering high-performance battery solutions.