When selecting a high-performance Lithium Iron Phosphate (LFP) battery, understanding the various factors that contribute to its quality is essential. This article will guide you through the key attributes to consider, including cell quality, raw materials, manufacturing processes, and performance metrics. We will also highlight the advantages of choosing SPIDERWAY LFP batteries, which utilize top-tier cells from leading manufacturers like BYD and CATL, ensuring exceptional quality and reliability.

**** Cell Quality

The core of any LFP battery is its cell quality. High-quality cells are crucial for ensuring longevity and performance. When evaluating LFP batteries, consider the following:

- Source of Cells: Opt for batteries that use A-grade cells from reputable manufacturers. SPIDERWAY sources its cells from industry leaders such as BYD and CATL, known for their rigorous quality control and advanced technology.

- Testing Standards: Quality cells undergo extensive testing for safety and performance. Ensure that the manufacturer provides documentation on their testing procedures.

**** Raw Materials

The choice of raw materials significantly impacts the battery’s overall quality and safety:

- Material Integrity: High-quality LFP batteries use pure iron phosphate as a cathode material. Inferior batteries may use substandard materials that can compromise performance.

- Environmental Considerations: SPIDERWAY emphasizes sustainability by using non-toxic materials that are easy to recycle, aligning with global environmental standards.

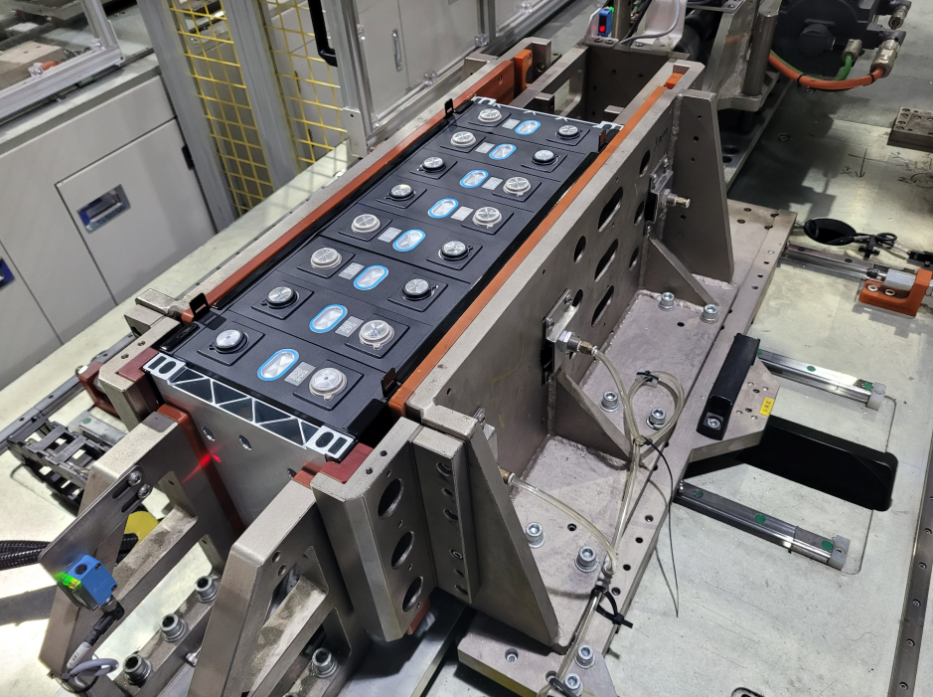

**** Manufacturing Processes

The manufacturing process is critical in determining battery quality:

- Precision Engineering: A well-designed manufacturing process minimizes defects and ensures consistent performance. SPIDERWAY employs state-of-the-art automated production lines to maintain high standards in battery assembly.

- Battery Management System (BMS): A reliable BMS is essential for monitoring battery health and safety. SPIDERWAY’s batteries are equipped with advanced BMS technology that ensures safe operation during charging and discharging cycles.

**** Performance Metrics

Evaluating performance metrics can help you gauge the suitability of an LFP battery for your needs:

- Cycle Life: Look for batteries that offer a long cycle life (thousands of charge-discharge cycles). SPIDERWAY batteries are designed for durability, providing up to 10 years of service life backed by a robust warranty.

- Charging Speed: Fast charging capabilities can significantly reduce downtime. SPIDERWAY’s LFP batteries support rapid charging, making them ideal for applications requiring quick energy replenishment.

- Safety Ratings: Ensure the battery has passed stringent safety tests and holds international certifications such as UL, CE, FCC, and ROHS. SPIDERWAY products meet these rigorous standards, providing peace of mind regarding safety.

When choosing a high-quality LFP battery, focus on cell quality, raw materials, manufacturing processes, and performance metrics. By selecting SPIDERWAY LFP batteries, you benefit from superior cell sourcing from BYD and CATL, meticulous manufacturing practices, and a commitment to safety and sustainability. This combination ensures you receive a reliable power solution tailored to meet your high-performance needs.