When considering the purchase of a forklift battery, price is a critical factor for businesses aiming to balance operational efficiency with cost management. Forklift batteries come in different types, each with unique pricing characteristics. In this article, we will explore the key factors influencing forklift battery prices, with a particular focus on LFP (Lithium Iron Phosphate) batteries and how the pricing of these batteries differs from others. Additionally, we will introduce SPIDERWAY LFP forklift batteries, a competitive product in the global market.

Types of Forklift Batteries and Their Pricing Differences

There are three main types of forklift batteries in use today: Lead-Acid, Nickel-Cadmium (NiCd), and Lithium-Ion, particularly LFP (Lithium Iron Phosphate). Each type varies in price due to factors like technology, lifespan, charging efficiency, and overall performance. Let’s briefly compare the pricing aspects of these battery types:

- Lead-Acid Batteries

The most common and affordable option, lead-acid batteries have a lower upfront cost. However, their shorter lifespan and frequent maintenance requirements can lead to higher long-term costs. Despite being budget-friendly initially, the need for regular water refilling, ventilation during charging, and potential for acid spills make them less efficient over time. - Nickel-Cadmium (NiCd) Batteries

NiCd batteries are less common in forklift applications due to their high cost and environmental concerns. They are durable and can handle extreme temperatures but come with a significantly higher price tag compared to lead-acid batteries. NiCd batteries are also subject to strict regulations regarding disposal due to their toxic components. - Lithium-Ion Batteries (LFP Forklift Batteries)

LFP batteries represent a significant technological advancement. While they may have a higher upfront cost than lead-acid batteries, their long lifespan, reduced maintenance needs, and faster charging times make them the most cost-effective option in the long run. Their stable chemical structure also makes them safer to use, offering excellent thermal and chemical stability, reducing the risks of overheating or combustion.

Factors That Influence LFP Forklift Battery Prices

Although LFP forklift batteries are more expensive upfront, several factors influence their price, making them a worthwhile investment for many businesses:

- Raw Material Costs

LFP batteries are primarily made from lithium iron phosphate, a compound that has seen fluctuating prices in recent years. The cost of raw materials directly impacts the overall battery price, especially when global supply chains are disrupted. However, compared to other lithium-ion chemistries, LFP batteries benefit from relatively abundant and less expensive materials, making them more affordable than other lithium-ion options like NMC (Nickel Manganese Cobalt). - Production Scale and Automation

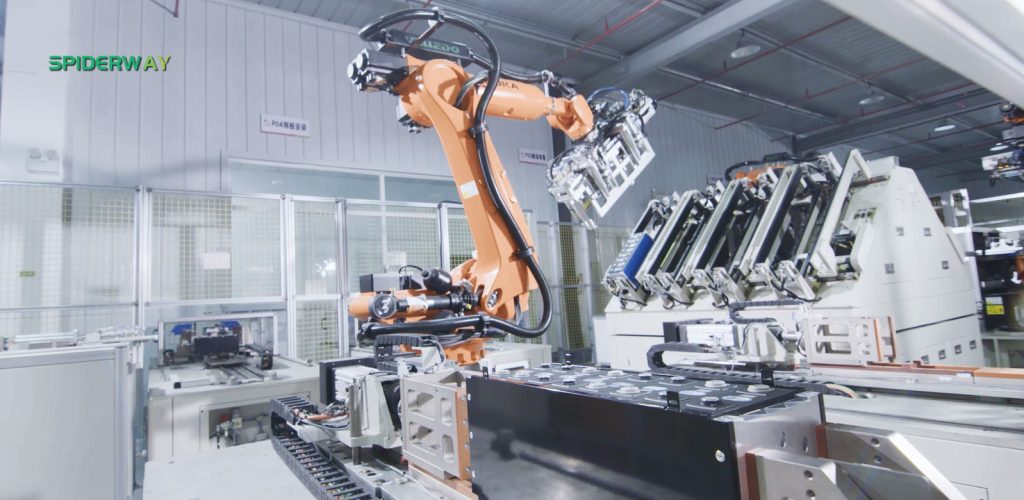

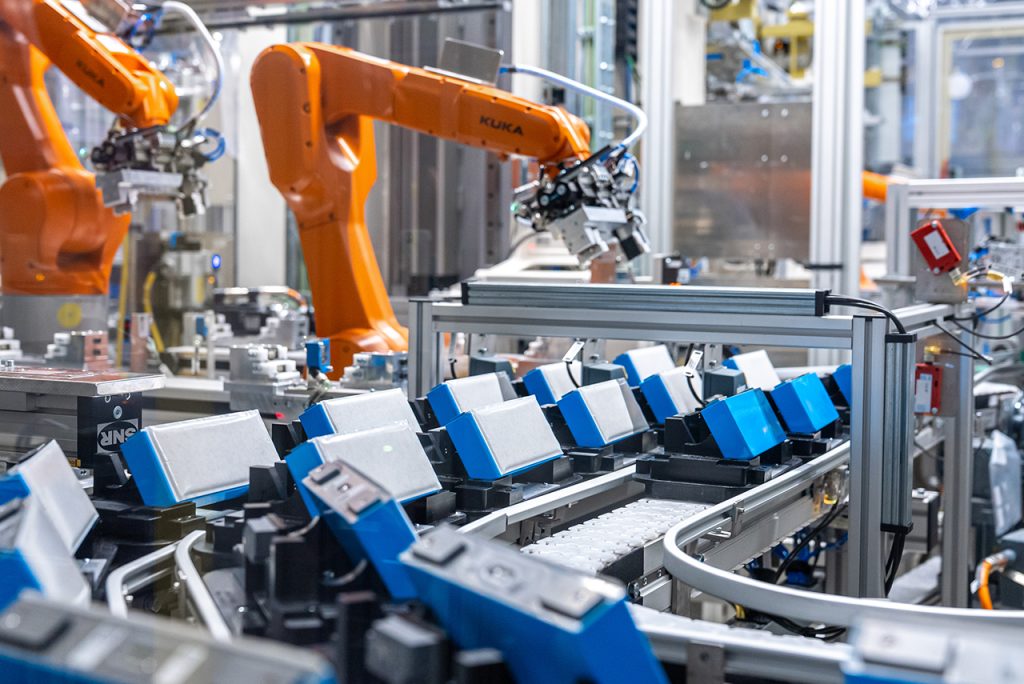

The scale of production significantly affects battery pricing. Manufacturers like SPIDERWAY, located in China’s powerhouse for energy storage solutions, benefit from large-scale automated production lines. Automation reduces labor costs and increases production efficiency, which directly contributes to more competitive pricing.

- Supply Chain Integration

Being located in the center of China’s lithium battery industry gives SPIDERWAY a unique advantage. The proximity to key suppliers, including raw material producers and component manufacturers, helps reduce transportation costs and lead times. A well-integrated supply chain leads to cost savings that can be passed on to the end customer. - Technological Advancements

Ongoing research and development in battery technology have led to continuous improvements in LFP battery performance. As batteries become more energy-dense and efficient, manufacturers can produce more powerful batteries at a lower cost per kilowatt-hour, further driving down prices. - Market Demand and Competition

The global shift toward electric vehicles (EVs) and the increasing use of electric forklifts have driven demand for lithium-ion batteries, including LFP. As competition grows, particularly from manufacturers in China, prices are expected to stabilize or even decrease, as companies strive to offer competitive pricing without compromising quality.

Why Choose SPIDERWAY LFP Forklift Batteries?

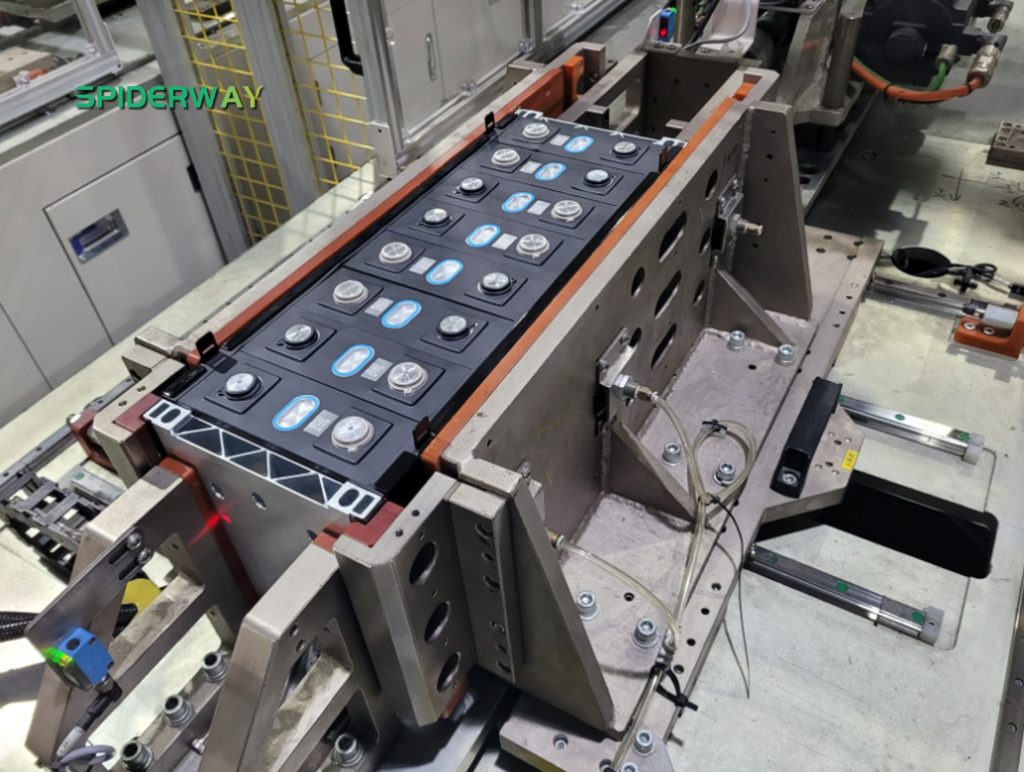

SPIDERWAY offers a range of LFP forklift batteries designed to meet the high-performance needs of modern industrial applications. Leveraging its strategic location in China’s battery production hub, SPIDERWAY ensures that its customers benefit from:

- Competitive Pricing: Thanks to large-scale production and efficient supply chains, SPIDERWAY can offer high-quality LFP forklift batteries at a competitive price point.

- Superior Performance: SPIDERWAY’s LFP batteries are designed for longevity, reduced maintenance, and faster charging, making them the optimal choice for businesses looking to lower total ownership costs.

- Global Reach: With extensive international shipping capabilities, SPIDERWAY provides fast delivery to customers worldwide, ensuring quick access to replacement batteries or new purchases.

The price of a forklift battery depends on a variety of factors, including battery type, raw material costs, production efficiency, and market demand. Among the different battery options, LFP forklift batteries offer a compelling balance of performance and cost-effectiveness, especially when sourced from a reputable manufacturer like SPIDERWAY. By taking advantage of economies of scale and a well-integrated supply chain, SPIDERWAY delivers high-quality LFP batteries at prices that are hard to beat.

If you are looking for a long-lasting, low-maintenance, and safe forklift battery, consider SPIDERWAY LFP forklift batteries—the smart choice for today’s industrial power needs.

Content Keywords: Forklift battery prices, LFP forklift batteries, Lithium Iron Phosphate forklift battery, Lead-acid forklift battery, Nickel-Cadmium forklift battery, SPIDERWAY LFP battery, industrial forklift battery pricing.