When it comes to charging lead-acid batteries and LFP (Lithium Iron Phosphate) batteries, using the same charger is generally not advisable. While both battery types may have similar voltage ratings for certain configurations (e.g., a 12V pack), their charging requirements differ significantly.

Differences in Charging Profiles:

- Voltage Tolerance: Lead-acid chargers typically apply a float charge to maintain battery health, which is not suitable for lithium batteries. Lithium batteries cannot tolerate float charging and can be damaged if subjected to such conditions[1][7].

- Charge Stages: Lead-acid chargers often operate on a multi-stage charging process (bulk, absorption, and float), while LFP batteries require a simpler constant current/constant voltage (CC/CV) approach. The float stage in lead-acid chargers can lead to overcharging in lithium batteries, reducing their lifespan or causing safety issues[8][9].

- Charging Speed: Lithium batteries can be charged significantly faster than lead-acid batteries. For example, a lithium battery can be fully charged in under two hours, whereas lead-acid batteries may take several hours[5][6].

In conclusion, while there might be some compatibility at nominal voltage levels, it is crucial to use a charger specifically designed for the type of battery being charged to ensure safety and longevity.

Characteristics of a Quality Forklift Lithium Battery Charger

When selecting a forklift lithium battery charger, several key features and qualities should be considered to ensure optimal performance and safety:

- Compatibility: Ensure that the charger is specifically designed for lithium-ion chemistry, particularly LFP batteries. This includes matching the voltage and current specifications to the battery’s requirements.

- Smart Charging Features: Modern chargers often come equipped with smart technology that automatically adjusts the charging profile based on the battery’s state of charge. This helps prevent overcharging and optimizes charging times[2][3].

- Safety Features: Look for chargers with built-in safety mechanisms such as temperature monitoring, short-circuit protection, and automatic shut-off when charging is complete. These features are crucial for preventing accidents and maintaining battery health[4][6].

- Energy Efficiency: Choose chargers that are energy-efficient to reduce operating costs over time. Chargers that comply with energy-saving standards can also contribute to more sustainable operations[3].

- User-Friendly Interface: A clear and intuitive user interface can simplify the charging process, making it easier for operators to monitor progress and manage multiple batteries effectively[4].

- Durability and Build Quality: A robust design that can withstand the rigors of industrial environments is essential. Chargers should be made from high-quality materials to ensure longevity and reliability[2][3].

In summary, investing in a high-quality forklift lithium battery charger with these characteristics will enhance operational efficiency, extend battery life, and ensure safety during charging.

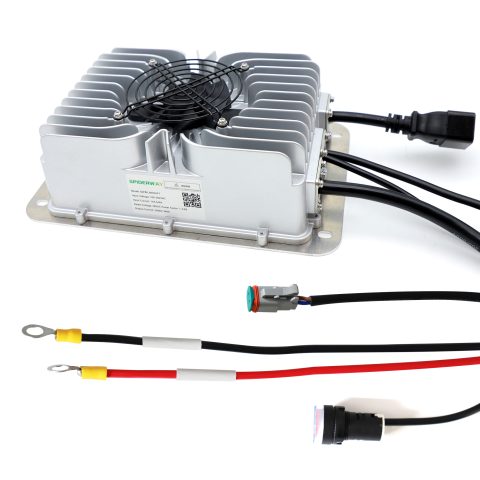

Introducing SPIDERWAY LFP Lithium Battery Charger

- Product on saleFlexChar 36V 25A 900W Industrial Battery Charger For Golf Cart/Electric Forklift/Electric VehicleOriginal price was: $350.00.$339.00Current price is: $339.00.

- Product on saleFlexChar 24V 18A 420W Industrial Battery Charger For Golf Cart/Electric Forklift/Electric VehicleOriginal price was: $300.00.$289.00Current price is: $289.00.

- Product on sale29.4V 6A XilLin Electric Pallet Truck Lithium battery ChargerOriginal price was: $199.00.$100.00Current price is: $100.00.

- Product on sale48V 6A XilLin Electric Pallet Truck Lithium battery ChargerOriginal price was: $199.00.$100.00Current price is: $100.00.

- Product on sale24V 5A EP Electric Pallet Truck Lithium Battery ChargerOriginal price was: $120.00.$100.00Current price is: $100.00.

- Product on sale48V 30A lead-acid battery Battery Charger for Genie/JLG/SWLLIFT/Skyjack Aerial PlatformOriginal price was: $350.00.$200.00Current price is: $200.00.

- Product on sale48V 30A Lithium Battery Charger for Genie/JLG/SWLLIFT/Skyjack Aerial PlatformOriginal price was: $250.00.$199.99Current price is: $199.99.

- Product on sale24V 25A Lead-acid Battery Charger For Aerial PlatformsOriginal price was: $300.00.$199.99Current price is: $199.99.

- Product on sale24V 25A Lithium Battery ChargerOriginal price was: $300.00.$199.99Current price is: $199.99.

SPIDERWAY offers top-of-the-line LFP lithium battery chargers designed specifically for optimal performance with lithium-ion technology. Our chargers feature advanced smart technology for efficient charging cycles, ensuring your forklifts are always ready for operation. With built-in safety mechanisms and energy-efficient designs, SPIDERWAY chargers not only protect your investment but also contribute to sustainable practices in your operations. Choose SPIDERWAY for reliability, quality, and exceptional customer support in your lithium battery charging needs.