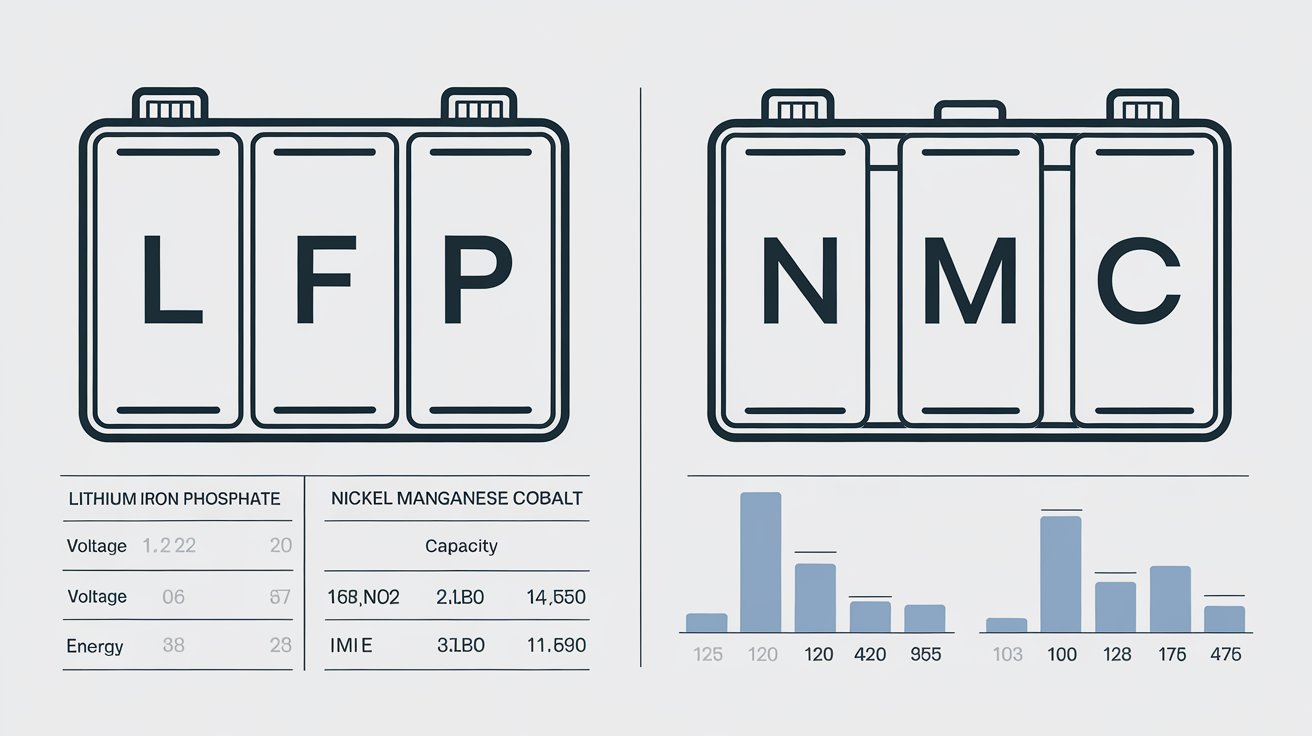

Lithium iron phosphate (LFP) and nickel-cobalt-manganese (NMC) lithium batteries have been the subject of much debate in the EV and energy storage industries. Here’s a detailed comparison of these two technologies:

Materials:

- LFP batteries use lithium iron phosphate as the cathode material, known for its stability and safety .

- NMC batteries use a combination of nickel, cobalt, and manganese for the cathode, offering high energy density .

Performance:

- LFP batteries have excellent safety performance and a longer cycle life, typically reaching 2000-3500 cycles .

- NMC batteries offer higher energy density, which translates to longer driving ranges for EVs but may have shorter cycle life compared to LFP .

Price:

- LFP batteries are generally more cost-effective due to the abundance and lower cost of iron and phosphate compared to cobalt and nickel .

- NMC batteries are typically more expensive due to the use of cobalt, a scarce and expensive metal .

Application Scenarios:

- LFP batteries are widely used in electric vehicles, energy storage systems, and power tools due to their safety and longevity .

- NMC batteries are prevalent in high-end electric vehicles where high energy density and specific power are required .

Environmental Impact:

- LFP batteries are considered more environmentally friendly due to the use of less toxic materials .

- NMC batteries require cobalt, the mining of which has been associated with environmental and social issues .

Lifespan:

- LFP batteries have a longer lifespan, often lasting 8-10 years or more under normal use .

- NMC batteries may have a shorter lifespan, typically 5-8 years, depending on usage and maintenance .

Charge Cycles:

- LFP batteries can withstand more charge cycles, making them suitable for applications requiring frequent charging and discharging .

- NMC batteries have fewer charge cycles but offer faster charging times .

Power:

- LFP batteries have high discharge power, making them ideal for applications requiring high power delivery .

- NMC batteries provide high specific energy, which is beneficial for applications requiring high energy storage in a small form factor .

Load Capacity:

- LFP batteries can handle high loads and are less susceptible to performance degradation under heavy loads .

- NMC batteries may experience faster capacity fade under continuous high-load conditions .

48V 304AH LiFePO4 lithium battery for KOMATSU Forklift FB20-12 Type

48V 304AH LiFePO4 lithium battery for KOMATSU Forklift FB20-12 Type- Product on sale

48V 404Ah LiFePO4 lithium battery for LIUGONG forkliftOriginal price was: $5,399.00.$5,318.00Current price is: $5,318.00.

48V 404Ah LiFePO4 lithium battery for LIUGONG forkliftOriginal price was: $5,399.00.$5,318.00Current price is: $5,318.00. - Product on sale

48V 606Ah LiFePO4 lithium battery for HELI forkliftOriginal price was: $7,999.00.$7,978.00Current price is: $7,978.00.

48V 606Ah LiFePO4 lithium battery for HELI forkliftOriginal price was: $7,999.00.$7,978.00Current price is: $7,978.00. - Product on sale

80V 404Ah LiFePO4 lithium battery for HELI K2 3.5T forkliftOriginal price was: $8,399.00.$8,310.00Current price is: $8,310.00.

80V 404Ah LiFePO4 lithium battery for HELI K2 3.5T forkliftOriginal price was: $8,399.00.$8,310.00Current price is: $8,310.00. - Product on sale

48V 404Ah LiFePO4 lithium battery for LIUGONG 2.5TforkliftOriginal price was: $5,399.00.$5,318.00Current price is: $5,318.00.

48V 404Ah LiFePO4 lithium battery for LIUGONG 2.5TforkliftOriginal price was: $5,399.00.$5,318.00Current price is: $5,318.00. - Product on sale

80V 544Ah LiFePO4 lithium battery for TOYOTA forkliftOriginal price was: $11,199.00.$11,190.00Current price is: $11,190.00.

80V 544Ah LiFePO4 lithium battery for TOYOTA forkliftOriginal price was: $11,199.00.$11,190.00Current price is: $11,190.00. - Product on sale

48V 272Ah LiFePO4 lithium battery for LIUGONG forkliftOriginal price was: $3,599.00.$3,581.00Current price is: $3,581.00.

48V 272Ah LiFePO4 lithium battery for LIUGONG forkliftOriginal price was: $3,599.00.$3,581.00Current price is: $3,581.00. - Product on sale

24V 202Ah LiFePO4 lithium battery for LINDE T20 forkliftOriginal price was: $1,399.00.$1,329.00Current price is: $1,329.00.

24V 202Ah LiFePO4 lithium battery for LINDE T20 forkliftOriginal price was: $1,399.00.$1,329.00Current price is: $1,329.00. - Product on sale

48V 544Ah LiFePO4 lithium battery for HELI CPD20-F1 forkliftOriginal price was: $7,199.00.$7,162.00Current price is: $7,162.00.

48V 544Ah LiFePO4 lithium battery for HELI CPD20-F1 forkliftOriginal price was: $7,199.00.$7,162.00Current price is: $7,162.00.

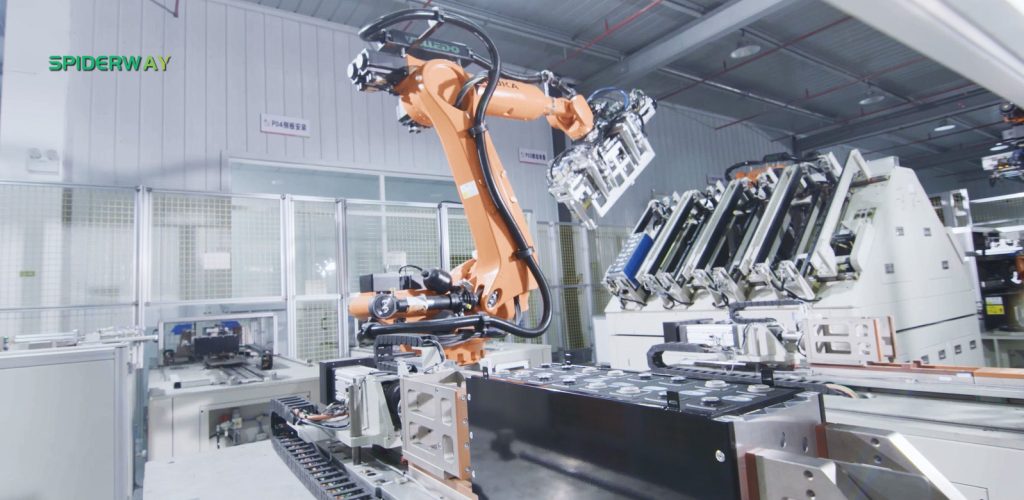

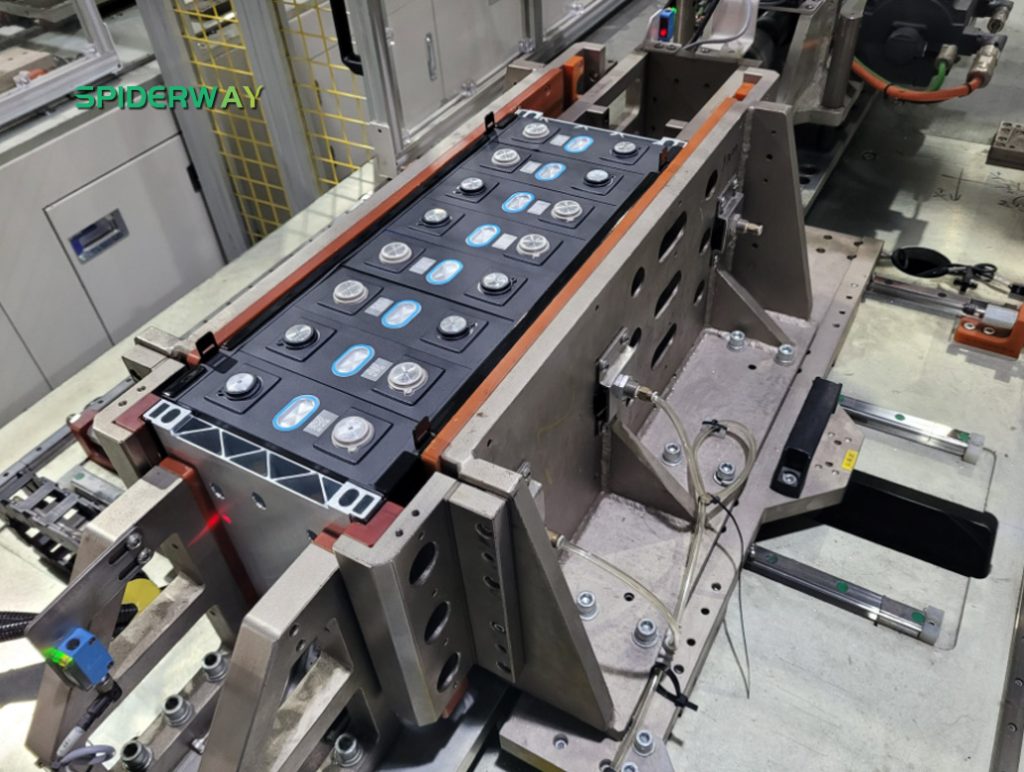

In the industrial vehicle sector, where high power and capacity are required, LFP batteries are gaining traction due to their safety, reliability, and cost-effectiveness. SPIDERWAY LFP Industrial Vehicle Lithium Batteries stand out in this field. With a focus on LFP battery production.

SPIDERWAY has established a robust production line and a diverse product range catering to various industrial vehicle applications. Their expertise and influence in the industrial vehicle lithium battery sector are growing, making them a preferred choice for many manufacturers looking to enhance the performance and safety of their vehicles .

Author Profile

- https://tawk.to/chat/6228c78d1ffac05b1d7dc569/1ftnkn0nk

- SpiderWay LiFePO4 battery sales engineer with ten years of experience in industrial vehicle batteries, ready to answer any questions you may have about industrial LiFePO4 battery products.

Latest entries

BetcoNovember 16, 2024Electric Floor Cleaners Cleaning Machines LFP Power Lithium Battery OEM Manufacturer Recommendations

Battery Charger KnowledgeNovember 16, 2024LFP (LiFePO4) Battery Charger Supplier from China: The Ultimate Solution for EV and Renewable Energy Applications

Industry NewsNovember 15, 2024China ESS Energy Storage Battery Manufacturers: Industry Development Data and Future Market Trends

Cleaning MachinesNovember 15, 2024Global Leading Cleaning Machines Brands & LFP Lithium Battery Solutions: Powering the Future of Cleaning Technology