Lithium Iron Phosphate (LFP) batteries are increasingly popular due to their safety, longevity, and cost-effectiveness. The production process of LFP batteries involves several intricate steps, starting from raw materials to the final assembly of the battery for use in vehicles. Below is a detailed overview of this process.

Production Process of LFP Batteries

1. Raw Material Extraction

- Lithium: Lithium is primarily sourced from lithium-rich minerals such as spodumene or from brine deposits. The extraction involves crushing the ore, followed by chemical processes to isolate lithium carbonate or lithium hydroxide.

- Iron: Iron is obtained from iron ore through mining and refining processes. Commonly used iron salts include iron sulfate (FeSO4) and iron chloride (FeCl3).

- Phosphoric Acid: Phosphoric acid is produced by reacting phosphate rock with sulfuric acid, followed by purification processes to ensure high purity.

2. Material Preparation

- Cathode Material Preparation: The cathode material, lithium iron phosphate (LiFePO4), is synthesized by mixing lithium carbonate, phosphoric acid, and iron salts. This mixture is then heated in a kiln at temperatures ranging from 700°C to 800°C to form the olivine structure essential for battery performance.

- Anode Material Preparation: The anode typically consists of graphite. Graphite powder is mixed with a binder and coated onto copper foil to create an anode sheet.

3. Electrolyte Formulation

The electrolyte, crucial for ion transport within the battery, consists of organic solvents mixed with lithium salts. The formulation must be precisely controlled to ensure optimal conductivity and stability.

4. Battery Assembly

The assembly process involves stacking the prepared cathode and anode sheets with a separator in between to prevent short circuits. This stack is then placed in a casing, where the electrolyte is added.

5. Formation Process

Once assembled, the battery undergoes a formation process that includes multiple charge and discharge cycles. This step activates the materials and stabilizes their performance characteristics.

6. Testing and Quality Control

After formation, batteries are subjected to rigorous testing:

- Capacity Testing: Evaluates the energy storage capability.

- Cycle Life Testing: Assesses how many charge-discharge cycles the battery can endure before significant capacity loss occurs.

- Safety Testing: Ensures the battery can withstand various stress conditions without failure.

7. Packaging and Inspection

Once testing is complete, batteries are packaged for shipment. This includes ensuring that they meet safety standards and performance specifications.

Standards for Quality LFP Batteries

High-quality LFP batteries should meet specific criteria:

- Safety Standards: Compliance with international safety certifications such as UL, CE, and IEC standards.

- Performance Metrics: High energy density (typically around 150 Wh/kg), excellent cycle life (up to 2000 cycles), and thermal stability.

- Purity of Materials: Use of high-purity lithium carbonate, phosphoric acid, and iron salts to ensure optimal performance.

- 48V 304AH LiFePO4 lithium battery for KOMATSU Forklift FB20-12 Type

- Product on sale48V 404Ah LiFePO4 lithium battery for LIUGONG forkliftOriginal price was: $5,399.00.$5,318.00Current price is: $5,318.00.

- Product on sale48V 606Ah LiFePO4 lithium battery for HELI forkliftOriginal price was: $7,999.00.$7,978.00Current price is: $7,978.00.

- Product on sale

80V 404Ah LiFePO4 lithium battery for HELI K2 3.5T forkliftOriginal price was: $8,399.00.$8,310.00Current price is: $8,310.00.

80V 404Ah LiFePO4 lithium battery for HELI K2 3.5T forkliftOriginal price was: $8,399.00.$8,310.00Current price is: $8,310.00. - Product on sale

48V 404Ah LiFePO4 lithium battery for LIUGONG 2.5TforkliftOriginal price was: $5,399.00.$5,318.00Current price is: $5,318.00.

48V 404Ah LiFePO4 lithium battery for LIUGONG 2.5TforkliftOriginal price was: $5,399.00.$5,318.00Current price is: $5,318.00. - Product on sale

80V 544Ah LiFePO4 lithium battery for TOYOTA forkliftOriginal price was: $11,199.00.$11,190.00Current price is: $11,190.00.

80V 544Ah LiFePO4 lithium battery for TOYOTA forkliftOriginal price was: $11,199.00.$11,190.00Current price is: $11,190.00. - Product on sale

48V 272Ah LiFePO4 lithium battery for LIUGONG forkliftOriginal price was: $3,599.00.$3,581.00Current price is: $3,581.00.

48V 272Ah LiFePO4 lithium battery for LIUGONG forkliftOriginal price was: $3,599.00.$3,581.00Current price is: $3,581.00. - Product on sale

24V 202Ah LiFePO4 lithium battery for LINDE T20 forkliftOriginal price was: $1,399.00.$1,329.00Current price is: $1,329.00.

24V 202Ah LiFePO4 lithium battery for LINDE T20 forkliftOriginal price was: $1,399.00.$1,329.00Current price is: $1,329.00. - Product on sale

48V 544Ah LiFePO4 lithium battery for HELI CPD20-F1 forkliftOriginal price was: $7,199.00.$7,162.00Current price is: $7,162.00.

48V 544Ah LiFePO4 lithium battery for HELI CPD20-F1 forkliftOriginal price was: $7,199.00.$7,162.00Current price is: $7,162.00.

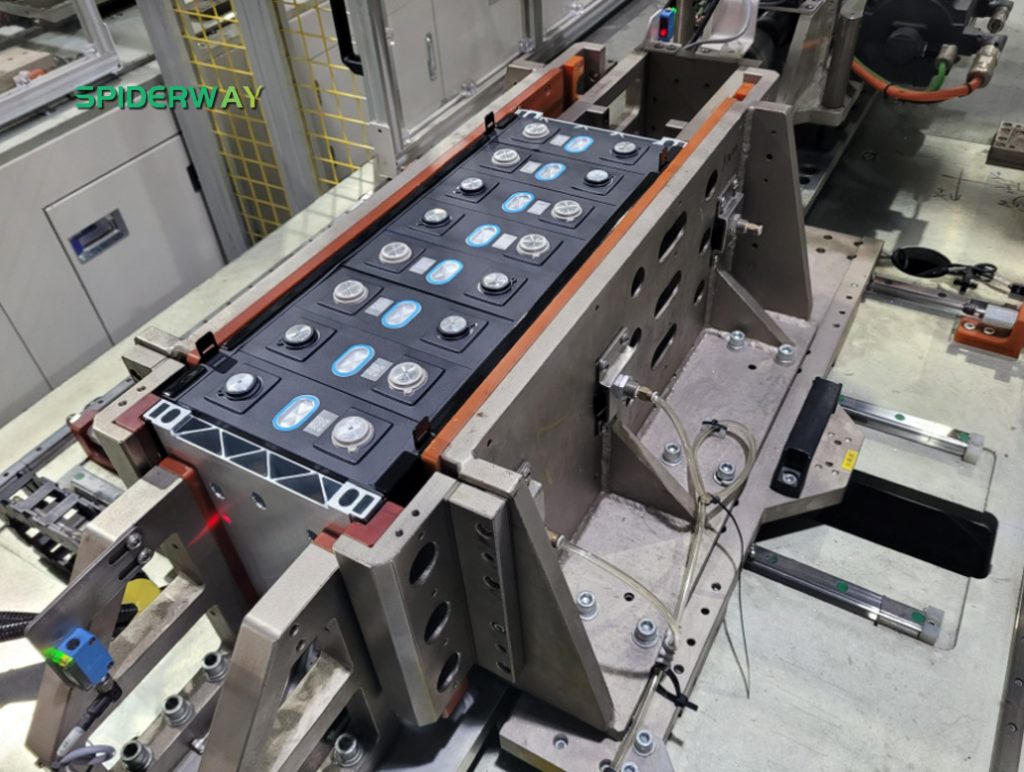

SPIDERWAY LFP Battery Advantages

SPIDERWAY stands out in the market by offering premium LFP batteries that utilize A-grade cells sourced exclusively from top-tier suppliers such as CATL, BYD, EVE Energy, and A123 Systems. This guarantees:

- High Performance: Delivering exceptional power output and efficiency.

- Stability: Enhanced thermal stability reduces risks associated with overheating.

- Longevity: Our batteries come with a remarkable lifespan supported by a robust warranty policy.

SPIDERWAY’s commitment to quality ensures that our LFP batteries are not only reliable but also environmentally friendly, contributing to a sustainable future in energy storage solutions.