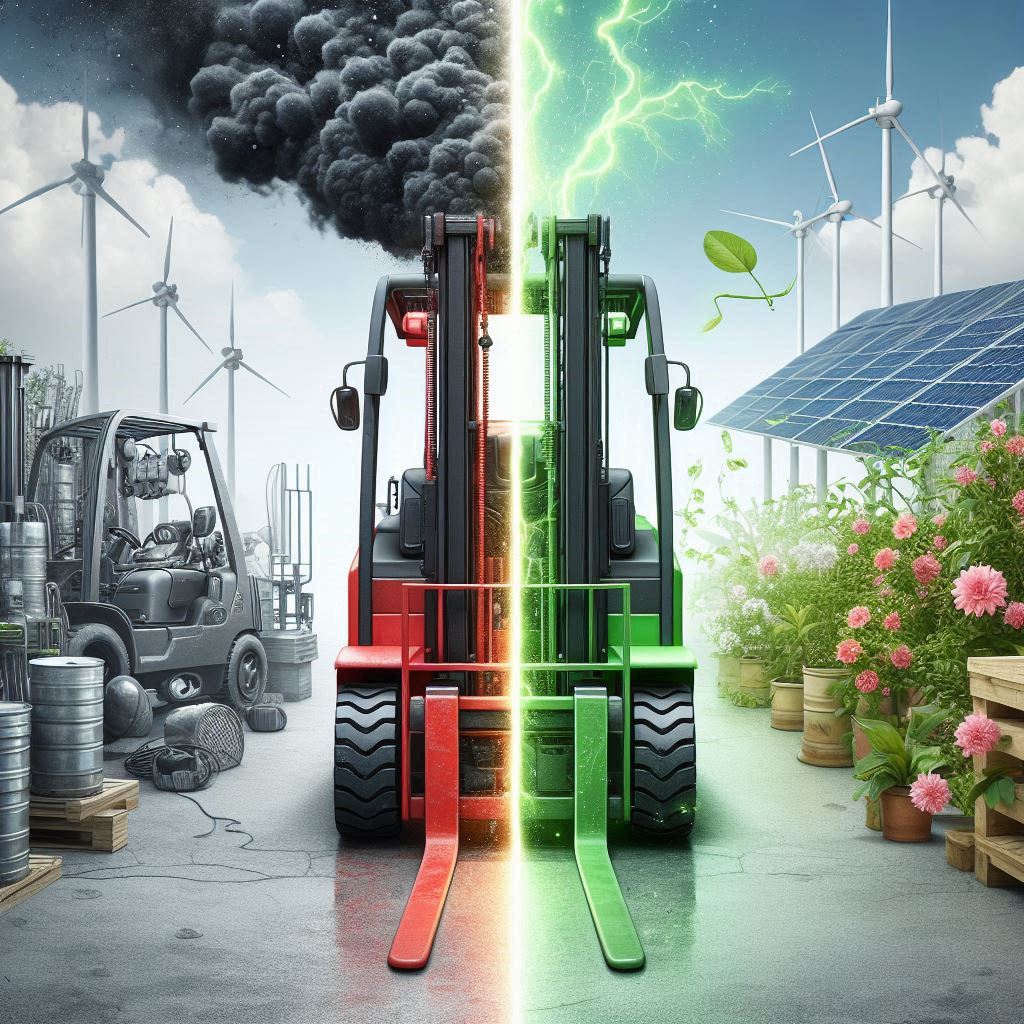

The lifecycle carbon emissions of a 2.5-ton diesel forklift can have significant environmental impacts. Diesel forklifts are widely used in various industries for material handling, but their reliance on fossil fuels contributes to greenhouse gas emissions, air pollution, and noise pollution. Understanding these emissions and the benefits of transitioning to electric forklifts is crucial for promoting sustainable practices in the workplace.

Lifecycle Carbon Emissions of a Diesel Forklift

A 2.5-ton diesel forklift typically emits around 1.5 to 2.5 tons of CO2 per year, depending on usage patterns and fuel efficiency. Over its lifespan, which can range from 10 to 15 years, the total carbon emissions can amount to approximately 15 to 37.5 tons of CO2. These emissions contribute to global warming and negatively impact air quality, posing health risks to workers and nearby communities. In addition to CO2, diesel forklifts emit nitrogen oxides (NOx) and particulate matter (PM), which can lead to respiratory problems and other health issues. The cumulative effect of these emissions underscores the need for cleaner alternatives.

Environmental Benefits of Electric Forklifts

Transitioning from diesel to electric forklifts presents numerous environmental benefits. Electric forklifts produce zero tailpipe emissions, significantly reducing the carbon footprint associated with material handling operations. This shift not only helps in mitigating climate change but also improves air quality in warehouses and manufacturing facilities. One of the leading solutions for this transition is the use of advanced lithium battery technology, such as the 80V 280Ah LiFePO4 lithium battery offered by SPIDERWAY. This battery is designed specifically for electric forklifts, providing a reliable and efficient power source. The advantages of using lithium batteries include:

- Higher Energy Efficiency: Lithium batteries have a higher energy density compared to traditional lead-acid batteries, allowing for longer operating times and reduced charging frequency.

- Reduced Maintenance: Lithium batteries require less maintenance, which translates to lower operational costs and less environmental impact from battery disposal.

- Longer Lifespan: With a lifespan of up to 10 years, lithium batteries reduce the need for frequent replacements, further decreasing waste.

SPIDERWAY’s Commitment to Social Responsibility

SPIDERWAY is committed to promoting sustainability and environmental responsibility through its innovative products. By providing high-quality lithium batteries for electric forklifts, SPIDERWAY supports the transition to cleaner energy solutions. The company recognizes its role in reducing carbon emissions and is dedicated to developing technologies that minimize environmental impact. In addition to producing environmentally friendly products, SPIDERWAY engages in community initiatives aimed at raising awareness about sustainability. The company believes that corporate responsibility extends beyond profit-making; it includes a commitment to fostering a healthier planet for future generations.

80V 280Ah LiFePO4 lithium battery for Oil-to-electric forklift truck models

Technical specifications: Voltage(V): 80V Capacity(Ah): 280AH Battery type: LiFePO4 (lithium iron phosphate) Charging time: Fast charge compatible Operating temperature range: -20°C to 60°C Dimensions and weight: 610*525*700mm

The lifecycle carbon emissions of a 2.5-ton diesel forklift highlight the urgent need for cleaner alternatives in material handling. Transitioning to electric forklifts powered by advanced lithium batteries, such as those provided by SPIDERWAY, offers significant environmental benefits. By embracing these technologies, industries can reduce their carbon footprint, improve air quality, and contribute to a more sustainable future. SPIDERWAY’s dedication to social responsibility further emphasizes the importance of corporate engagement in environmental stewardship.