KUKA is a renowned German manufacturer of industrial robots and automation solutions, with a history that began in 1898 when it was founded as an acetylene gas factory in Augsburg, Germany . Over the years, KUKA has evolved to become a global player in the industrial robotics market, offering a comprehensive range of products and services designed to improve efficiency, productivity, and safety across various industries .

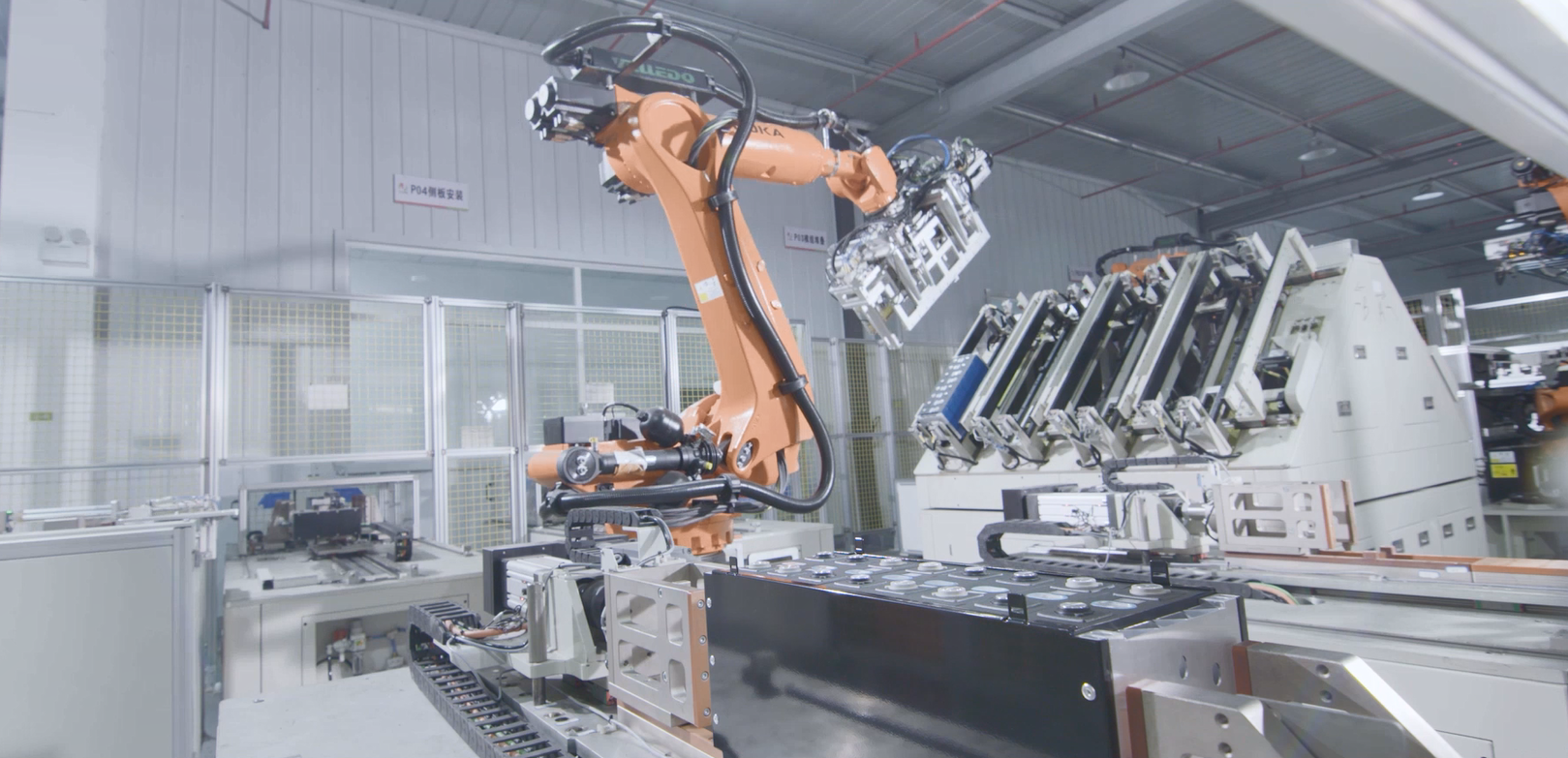

In the context of Large Format Pouch (LFP) battery production lines, KUKA’s industrial robots play a pivotal role in automating various processes, ensuring precision and efficiency. KUKA’s expertise in battery production systems extends across the entire value chain, providing automation solutions that are efficient, fast, safe, and environmentally friendly . This is particularly important in the booming demand for lithium-ion batteries, which are used in a variety of applications from smartphones to electric vehicles.

Taking the example of the SPIDERWAY factory, KUKA’s industrial robots could be utilized to streamline the production of LFP batteries. The application of KUKA robots in this setting can enhance the automation of critical processes such as stacking, loading and unloading, cell formation, and aging. Moreover, KUKA provides customer-specific overall concepts for each individual process step in battery production, which can be tailored to the unique requirements of SPIDERWAY’s LFP battery manufacturing .

- 48V 304AH LiFePO4 lithium battery for KOMATSU Forklift FB20-12 Type

- Product on sale48V 404Ah LiFePO4 lithium battery for LIUGONG forkliftOriginal price was: $5,399.00.$5,318.00Current price is: $5,318.00.

- Product on sale48V 606Ah LiFePO4 lithium battery for HELI forkliftOriginal price was: $7,999.00.$7,978.00Current price is: $7,978.00.

- Product on sale

80V 404Ah LiFePO4 lithium battery for HELI K2 3.5T forkliftOriginal price was: $8,399.00.$8,310.00Current price is: $8,310.00.

80V 404Ah LiFePO4 lithium battery for HELI K2 3.5T forkliftOriginal price was: $8,399.00.$8,310.00Current price is: $8,310.00. - Product on sale

48V 404Ah LiFePO4 lithium battery for LIUGONG 2.5TforkliftOriginal price was: $5,399.00.$5,318.00Current price is: $5,318.00.

48V 404Ah LiFePO4 lithium battery for LIUGONG 2.5TforkliftOriginal price was: $5,399.00.$5,318.00Current price is: $5,318.00. - Product on sale

80V 544Ah LiFePO4 lithium battery for TOYOTA forkliftOriginal price was: $11,199.00.$11,190.00Current price is: $11,190.00.

80V 544Ah LiFePO4 lithium battery for TOYOTA forkliftOriginal price was: $11,199.00.$11,190.00Current price is: $11,190.00. - Product on sale

48V 272Ah LiFePO4 lithium battery for LIUGONG forkliftOriginal price was: $3,599.00.$3,581.00Current price is: $3,581.00.

48V 272Ah LiFePO4 lithium battery for LIUGONG forkliftOriginal price was: $3,599.00.$3,581.00Current price is: $3,581.00. - Product on sale

24V 202Ah LiFePO4 lithium battery for LINDE T20 forkliftOriginal price was: $1,399.00.$1,329.00Current price is: $1,329.00.

24V 202Ah LiFePO4 lithium battery for LINDE T20 forkliftOriginal price was: $1,399.00.$1,329.00Current price is: $1,329.00. - Product on sale

48V 544Ah LiFePO4 lithium battery for HELI CPD20-F1 forkliftOriginal price was: $7,199.00.$7,162.00Current price is: $7,162.00.

48V 544Ah LiFePO4 lithium battery for HELI CPD20-F1 forkliftOriginal price was: $7,199.00.$7,162.00Current price is: $7,162.00.

SPIDERWAY’s LFP batteries can benefit from KUKA’s commitment to sustainable process technologies. KUKA’s automation solutions support the entire value chain of battery production, from precision laser machining and welding to associated measuring and inspection systems. This not only ensures high-quality battery production but also contributes to the environmental sustainability of the process .

Furthermore, KUKA’s engagement in innovative projects like DeMoBat, which focuses on the automated disassembly of electric vehicle batteries, demonstrates its dedication to supporting the automotive industry in achieving sustainable battery production and recycling .

In summary, KUKA’s advanced robotics and automation solutions are instrumental in the efficient and sustainable production of LFP batteries, as exemplified by their potential application in a SPIDERWAY factory setting. The integration of KUKA’s technology into SPIDERWAY’s production line could significantly enhance the manufacturing process, ensuring high standards of quality and environmental responsibility.